-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Shop Made Boring Head Project

- Thread starter Smudgemo

- Start date

Re: Shop Made Boring Head Project--a real INSPIRATION

you are a real inspiration for the rest of us here on hm. the workmanship on your boring head is excellent . been looking on internet for plans to build a homemade boring head and will post links here ---- so others can surf the net if they wish. thanks again for the excellent pics and write up. u do excellent machine work. links here--http://www.deansphotographica.com/machining/projects/mill/boring/boring.html and also link here --

http://homepage3.nifty.com/amigos/boring_head/boring_head-e.htm

another link here--http://homepage3.nifty.com/amigos/boring_head/boring_head-e.htm. not trying to steal ur thread--just tryin to help others. enjoy! re steve in mt.

you are a real inspiration for the rest of us here on hm. the workmanship on your boring head is excellent . been looking on internet for plans to build a homemade boring head and will post links here ---- so others can surf the net if they wish. thanks again for the excellent pics and write up. u do excellent machine work. links here--http://www.deansphotographica.com/machining/projects/mill/boring/boring.html and also link here --

http://homepage3.nifty.com/amigos/boring_head/boring_head-e.htm

another link here--http://homepage3.nifty.com/amigos/boring_head/boring_head-e.htm. not trying to steal ur thread--just tryin to help others. enjoy! re steve in mt.

- Joined

- Feb 7, 2013

- Messages

- 15

Hello Ryan,

A very nice project you've shared with us. Your description & photography during the build made the machining process very clear, especially on your innovative dovetail & gib. My Myford Super 7 lathe uses the same gib system (not tapered). On my lathe I added an additional lock screw in addition the the gib adjustment screws to lock the slide in place during machining that way I don't have to readjust anything once everything is sliding perfectly in the dovetail. Certainly not very important in the overall scheme of things but may further inhance the use of your already superb tool.

Rod Baker

A very nice project you've shared with us. Your description & photography during the build made the machining process very clear, especially on your innovative dovetail & gib. My Myford Super 7 lathe uses the same gib system (not tapered). On my lathe I added an additional lock screw in addition the the gib adjustment screws to lock the slide in place during machining that way I don't have to readjust anything once everything is sliding perfectly in the dovetail. Certainly not very important in the overall scheme of things but may further inhance the use of your already superb tool.

Rod Baker

- Joined

- Nov 2, 2012

- Messages

- 415

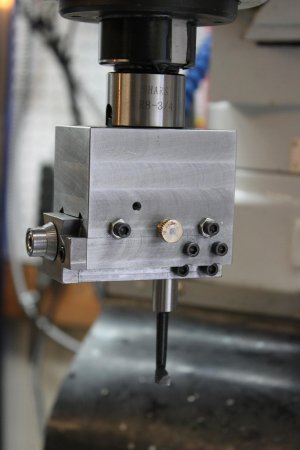

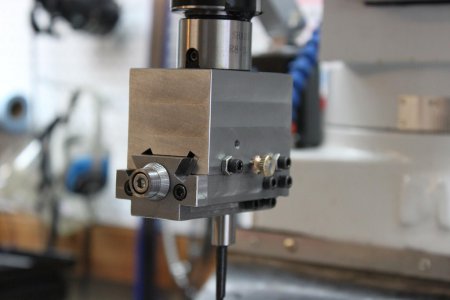

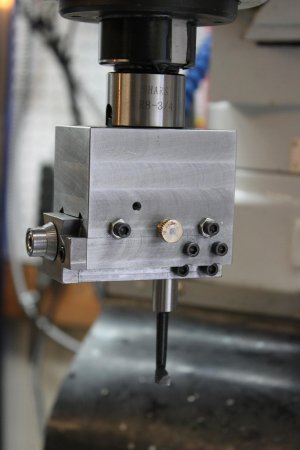

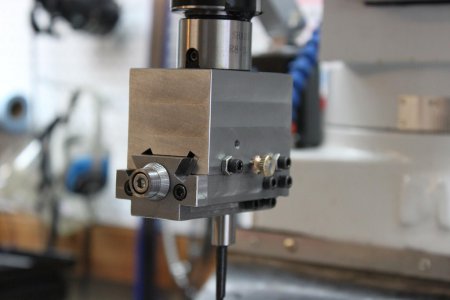

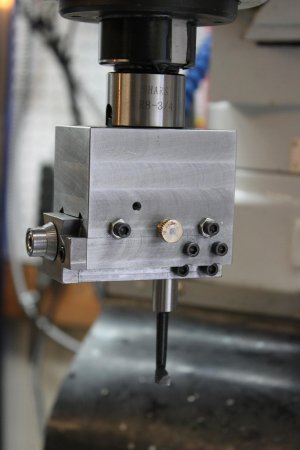

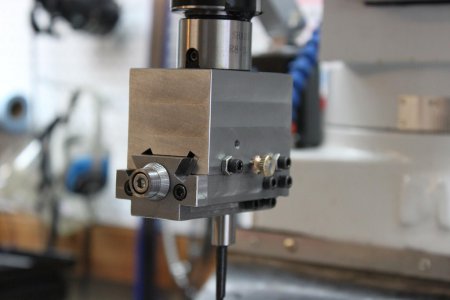

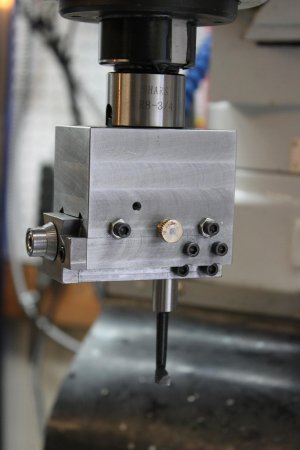

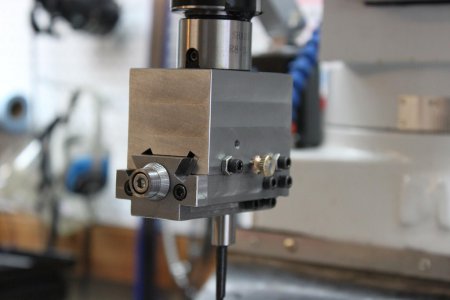

Just to wrap this project up, I finally got the boring bars, the hardware I wanted and a thumbscrew setup to lock the gib for actual use. I haven't ever used a boring head in a mill, so I was hoping this would at the very least work as well as some inexpensive overseas unit. Well, I can't say whether it's better or not, but it sure works well. I found a piece of aluminum stock that was bored with some sort of sloppy cut, and gave it a go. The results were excellent, and the ability to move the carrier by .001" ought to be plenty for my needs for awhile.

I silver-brazed the wheel to the machine screw. $1.30 or so for the parts at the local ACE.

Front view. I tried to clean up the machine marks a bit, but didn't take it any further.

Some action footage. Always with the music on, too.

[video=youtube_share;LAo6ukYaBrE]http://youtu.be/LAo6ukYaBrE[/video]

Now I need to start a project that will need bored holes, I guess.

Cheers!

-Ryan

I silver-brazed the wheel to the machine screw. $1.30 or so for the parts at the local ACE.

Front view. I tried to clean up the machine marks a bit, but didn't take it any further.

Some action footage. Always with the music on, too.

[video=youtube_share;LAo6ukYaBrE]http://youtu.be/LAo6ukYaBrE[/video]

Now I need to start a project that will need bored holes, I guess.

Cheers!

-Ryan

B

Bill Gruby

Forum Guest

Register Today

Is this the book? Loved the video.

http://www.ebay.com/itm/Milling-for...830?pt=US_Nonfiction_Book&hash=item48603013be

"Billy G"

http://www.ebay.com/itm/Milling-for...830?pt=US_Nonfiction_Book&hash=item48603013be

"Billy G"

- Joined

- Nov 2, 2012

- Messages

- 415

Is this the book? Loved the video.

http://www.ebay.com/itm/Milling-for...830?pt=US_Nonfiction_Book&hash=item48603013be

"Billy G"

Thanks, Bill.

That looks like it, but the cover is slightly different. This is the version that I've got:

http://www.amazon.com/Milling-Home-Machinists-Harold-Hall/dp/1565236947 . The reviews don't overwhelm you as awesome, but when you take the time to read them, you find people are complaining that the material is reprinted from other books he's done, or too advanced for the absolute beginner. He also has a lot of stuff on his website including plans for a small boring head and lots of other things: http://homews.co.uk/index.html

I should note again that the book is all in metric, so you need to either convert or work in metric. I chose to follow dimensions and place holes in metric via my DRO, but changed the fasteners to 8-32, the lead screw to 1/4-20, and any cut to 3/8" or 1/2" because I have those cutters on hand. So I complicated things, but it seems to have worked out. The plan that follows this one is a diving head that I may tackle at some point soon just because.

-Ryan

- Joined

- Dec 22, 2011

- Messages

- 715

Here's a link to Harold's website if that helps: http://www.homews.co.uk/page3.html

The site is a little difficult to navigate but has a lot of useful info.

Steve

The site is a little difficult to navigate but has a lot of useful info.

Steve

- Joined

- Feb 6, 2013

- Messages

- 99

"Impressive, most impressive.", Darth Vader - Empire Strikes Back on planet Bespin.