- Joined

- Feb 7, 2012

- Messages

- 541

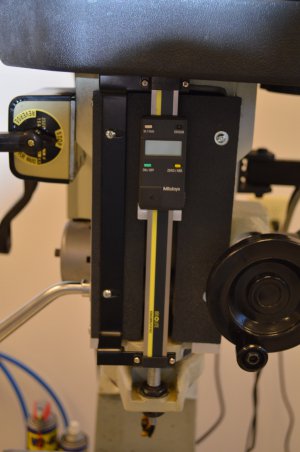

Thought I would post a little about my adventure. I think I am one to always look for the hard way to accomplish things, or so it seems with the first [part one] DRO I added to my small mill. It all went well, but I think I looked for a complicated way to install the readout to my ram. I could have just used the screw hole left over from the pointer I removed, but decided to center it instead, and thus the project began.

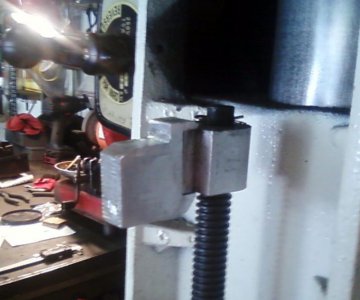

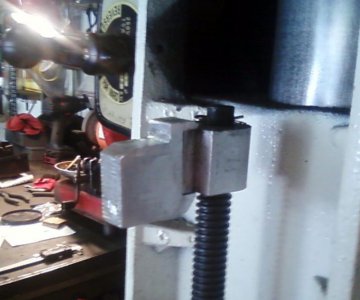

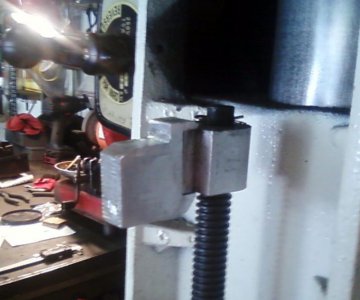

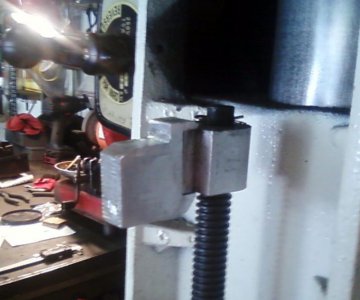

Anyhow, long story short, I picked up some smaller units from Dave (member here on the forum) and started with one yesterday. Surface mounting was fairly straight forward and went without a hitch, but connecting the slide to the reader to the down feed ram proved interesting. I ended up making an extension for the inner nut in the ram (?) inside the mill, and figured a way to secure it to the reader block (good ol' epoxy glue first, then a small screw). The whole unit just slides in/on over the inner nut when putting it on the front of the mill. Probably not explaining it right, but so far this is where I am at. Glue is curing now, so I'll get a pic tomorrow completely installed.

Don't laugh - it keeps my brain from snoozing all day long, coming up with these ideas. :think1:

Anyhow, long story short, I picked up some smaller units from Dave (member here on the forum) and started with one yesterday. Surface mounting was fairly straight forward and went without a hitch, but connecting the slide to the reader to the down feed ram proved interesting. I ended up making an extension for the inner nut in the ram (?) inside the mill, and figured a way to secure it to the reader block (good ol' epoxy glue first, then a small screw). The whole unit just slides in/on over the inner nut when putting it on the front of the mill. Probably not explaining it right, but so far this is where I am at. Glue is curing now, so I'll get a pic tomorrow completely installed.

Don't laugh - it keeps my brain from snoozing all day long, coming up with these ideas. :think1: