Anyone have experience with the Taig boring head for the mill? I need a boring head for my Taig mill that has ER16 collet; so, I need a boring head with a 3/8" shank for my largest collet. Suggestions are welcome.

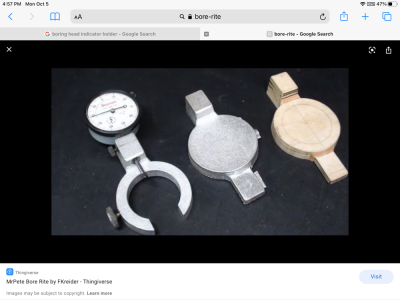

I think the Taig boring head would work just fine for me; except, it has no dial to measure movement. I don't know how accurate dials are anyway, so is a dial necessary? How does one go about accurately measuring the diameter that will be produced by a boring bar, anyway?

I think the Taig boring head would work just fine for me; except, it has no dial to measure movement. I don't know how accurate dials are anyway, so is a dial necessary? How does one go about accurately measuring the diameter that will be produced by a boring bar, anyway?