This is my version of a new handle for the tailstock.

My Taig is on a large board that just sits on my workbench and it has occasionally moved if I put too much pressure on the original handle, so I thought I would try for a handle that will allow a push and a pull at the same time to see if that would help. (I guess I could learn how to sharpen my drill bits, or at least buy new ones.)

I started with an eighth by half mild steel and duplicated the holes from the original steel, then cut the new piece to length, leaving about 2.5 to 3 inches beyond each hole.

I put a piece of 1 inch wooden dowel rod in the milling attachment/vice, and using an eighth inch Dremel burr in the collet, I cut a blind slot about 3/4 inch deep, as long as the cross slide travel would allow. My idea was to try to get the center of the steel in about the center of the wood. Once the slots were cut, I cut off the dowel at one edge of the slot and cut the other end leaving a 6 and a half inch piece and a 5 and a half piece. A little time on the sanding wheel eased the edges.

Again, using the milling attachment and vice, I drilled and counter sank the holes in the wood, more or less an inch apart, slightly beyond the slot to allow for the 8-32 x 1/2 socket flat head screws to bottom out in my counter sunk holes.

Then I fit the steel into the slot, and tapped it tight to the bottom and end of the slot and marked where I needed to drill the holes in the steel.

The steel was then drilled and tapped for 8-32 machine screws.

I didn't see much sense in the bolt and nut to hold the original handle in place, and the cotter pin was a nuisance, so I turned the "belaying" pins to hold the handle in place. I made the one that goes through the 2 straps a bit thicker to accommodate the larger holes in bracket. (It bothered me to have the original handle flopping around if I disconnected the cotter pin and left the bolt attached. With the 2 pins, it's a cinch to completely remove the handle when I am using a dead center on the tailstock.

I bit of stain and 3 coats of rub on poly on the wood and done!

Parts ready for assembly with the original steel next to my new one:

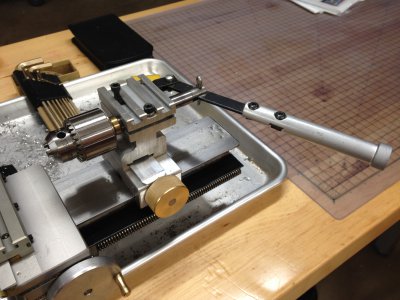

Assembled - notice a bit of reshaping to allow full in and out of the shaft:

Showing a one handed push/pull - could also use both hands:

My Taig is on a large board that just sits on my workbench and it has occasionally moved if I put too much pressure on the original handle, so I thought I would try for a handle that will allow a push and a pull at the same time to see if that would help. (I guess I could learn how to sharpen my drill bits, or at least buy new ones.)

I started with an eighth by half mild steel and duplicated the holes from the original steel, then cut the new piece to length, leaving about 2.5 to 3 inches beyond each hole.

I put a piece of 1 inch wooden dowel rod in the milling attachment/vice, and using an eighth inch Dremel burr in the collet, I cut a blind slot about 3/4 inch deep, as long as the cross slide travel would allow. My idea was to try to get the center of the steel in about the center of the wood. Once the slots were cut, I cut off the dowel at one edge of the slot and cut the other end leaving a 6 and a half inch piece and a 5 and a half piece. A little time on the sanding wheel eased the edges.

Again, using the milling attachment and vice, I drilled and counter sank the holes in the wood, more or less an inch apart, slightly beyond the slot to allow for the 8-32 x 1/2 socket flat head screws to bottom out in my counter sunk holes.

Then I fit the steel into the slot, and tapped it tight to the bottom and end of the slot and marked where I needed to drill the holes in the steel.

The steel was then drilled and tapped for 8-32 machine screws.

I didn't see much sense in the bolt and nut to hold the original handle in place, and the cotter pin was a nuisance, so I turned the "belaying" pins to hold the handle in place. I made the one that goes through the 2 straps a bit thicker to accommodate the larger holes in bracket. (It bothered me to have the original handle flopping around if I disconnected the cotter pin and left the bolt attached. With the 2 pins, it's a cinch to completely remove the handle when I am using a dead center on the tailstock.

I bit of stain and 3 coats of rub on poly on the wood and done!

Parts ready for assembly with the original steel next to my new one:

Assembled - notice a bit of reshaping to allow full in and out of the shaft:

Showing a one handed push/pull - could also use both hands:

Last edited: