-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tapping heads

- Thread starter Firstgear

- Start date

- Joined

- Nov 27, 2012

- Messages

- 7,854

- Joined

- May 4, 2015

- Messages

- 3,583

I have some old supreme versmatic tapping heads even a hand held type for a hand drill . They to use a clutch type response I've used this type and the procunier heads. Now I do have an ettco which mounts to the spindle on a drill press clamps to the outter part. Bought it some time ago. Before my pain stopped everything. But I must have tapped a few hundred thousand holes in silk screen frames at my first apprentice shop . All aluminum frames cast with 24 tapped holes in 10-32 + 10-24. After I faced both sides and squared the sides. I felt like the tin man after every day from just the sanding the sprues off. I don't remember ever breaking a tap using them . But I've broke my share using tap wrenches . So I like them

- Joined

- Feb 17, 2013

- Messages

- 4,406

British pronunciation of "tapping head," don't ya know?What's a yapping head ?

- Joined

- Jan 31, 2016

- Messages

- 11,437

I power tap in the mill , unless the threads are very small . I have to remove broken bolts from dies just about every night at work . I always hand tap these threads as the dies are hardened . I used my die heads on gang drill presses for production jobs years ago . I haven't done production work in 30 or so years .

I have to ask, when you tap what/how do you tap? By hand? By mill? ???

- Joined

- Nov 26, 2012

- Messages

- 1,307

I have a "Nikken-Coventry ZR-12" set up in my drill press that used to never get used (drill press that is).

Japanese I guess and I like it better than my Porcuner-1 that I have set up to use on the lathe.

Tap holder-clutch assemblies are quick change. not cheap that way but very convenient.

I drilled and threaded a cross bolt on the upper end of the mt2 taper.

Not gonna have that thing fall on the floor.

Japanese I guess and I like it better than my Porcuner-1 that I have set up to use on the lathe.

Tap holder-clutch assemblies are quick change. not cheap that way but very convenient.

I drilled and threaded a cross bolt on the upper end of the mt2 taper.

Not gonna have that thing fall on the floor.

- Joined

- May 4, 2019

- Messages

- 792

Unless I have a lot of holes to tap I usually power tap in the mill. For smaller taps I hand tap using a spring follower guide. For doing many holes I have a couple SPV tapping heads. They work well.

I used to have a Tapmatic head but unfortunately loaned it to a " friend". Same friend that crashed both my Tenthset boring heads.

I used to have a Tapmatic head but unfortunately loaned it to a " friend". Same friend that crashed both my Tenthset boring heads.

- Joined

- Jul 29, 2014

- Messages

- 2,728

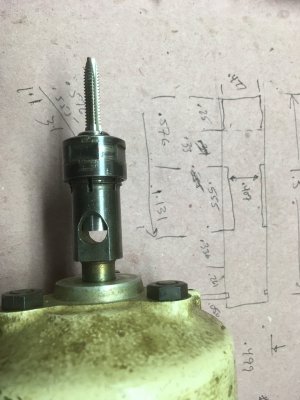

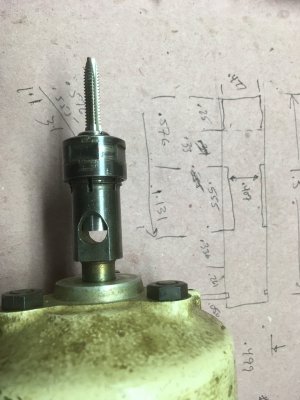

This is an older thread, but maybe this is relevant. I have a Procunier #2E tapping head that I have always not really known how to use it. I got it out the other day and made every mistake that I could figure out, now I think it's actually pretty cool and maybe would be worth setting up even if there were only one or two holes to tap. So much easier than hand tapping.

But in the learning process I had trouble with the 1/4-20 tap, ended up breaking the spiral flute tap. On examination, I found that my collet of that size had worn out, so that the little square feature inside the collet holding the tap from rotating was gone. So, let's make another, because they are $45 on eBay and it may only take a couple days to reproduce.

There were two main troubles in doing this. The first is the little square feature is internal and would need a broach or such. It's in the middle of two holes, one the tap size and the other a bit smaller. On reflection, I realized that the square feature could, without creating a problem of any kind, be made by cutting a square hole in one end of the tap, no need for the smaller hole. So I did that by drilling out a hole sized as the inscribed diameter of the square end of the collet, and ground a small HSS tool, put it in the lathe and like cutting a keyway, just whittled away at the corners of the hole until it looked square. As soon as I could get a tiny square file through there, I switched to the die filer and finished up that way. This worked well.

Next, the collet has three slits to allow compression around the tap. After pawing through my slitting saw collection, I found a small diameter 0.028' width saw and I used that. Holding the collet to slit it was a problem, but I squeezed it end to end in the mill vise and could leave enough hanging outside the vise to run the saw along the side. Worked out, but I had to eyeball the angular position of the three slits rather than use a collet block that I was hoping to do.

I tell you, the next one of these I make is going to be a snap.

(Note that I don't show a spiral flute tap in these pictures because I broke it. And you can see my CAD package in the background.)

But in the learning process I had trouble with the 1/4-20 tap, ended up breaking the spiral flute tap. On examination, I found that my collet of that size had worn out, so that the little square feature inside the collet holding the tap from rotating was gone. So, let's make another, because they are $45 on eBay and it may only take a couple days to reproduce.

There were two main troubles in doing this. The first is the little square feature is internal and would need a broach or such. It's in the middle of two holes, one the tap size and the other a bit smaller. On reflection, I realized that the square feature could, without creating a problem of any kind, be made by cutting a square hole in one end of the tap, no need for the smaller hole. So I did that by drilling out a hole sized as the inscribed diameter of the square end of the collet, and ground a small HSS tool, put it in the lathe and like cutting a keyway, just whittled away at the corners of the hole until it looked square. As soon as I could get a tiny square file through there, I switched to the die filer and finished up that way. This worked well.

Next, the collet has three slits to allow compression around the tap. After pawing through my slitting saw collection, I found a small diameter 0.028' width saw and I used that. Holding the collet to slit it was a problem, but I squeezed it end to end in the mill vise and could leave enough hanging outside the vise to run the saw along the side. Worked out, but I had to eyeball the angular position of the three slits rather than use a collet block that I was hoping to do.

I tell you, the next one of these I make is going to be a snap.

(Note that I don't show a spiral flute tap in these pictures because I broke it. And you can see my CAD package in the background.)