- Joined

- Mar 25, 2018

- Messages

- 131

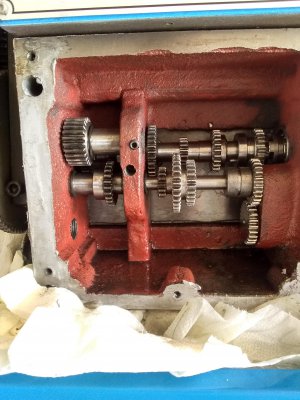

I'm chasing noises in my recently delivered 1127VF-LB. That required opening up the gearbox. The mystery noise does not originate therein; but I did see how the machine does its magic. Reminded me of a four speed tranny with wide gear spacing ....

Anyhow, long as I was in there, I took a pic to share with those who may wonder what's behind the cover. I was impressed with the cleanliness of the interior of the gearbox. Not a bit of swarf anywhere.

Going a bit deeper, I got inside the headstock. Found the source of the noise - bearing at the input side of the spindle shaft. But there's no decernable play and it runs true so I won't be premature in affecting a decision to replace it just yet. I did find that the speed control circuit board which is housed in the same area was contaminated with what appeared to be silver colored metal dust (perhaps the residue of a drilling operation) and because electronic circuits don't like that kind of stuff I did a compressed air cleanup.

UPDATE:

(For those who may need to remove and replace the gearbox cover for future maintenance)

Putting everything back in place requires a bit of adroit manipulation that would have been easier if I had four hands. Setting the feed direction, feed rate and feed/thread gears in their neutral positions and then "eyeballing" the alignment of the operating levers to mesh with the correct gear set worked best for me. I made a wooden block to just fit between the bottom of the gearbox and the tray and slipped it into place to support the cover whilst tipping the cover into place.

Anyhow, long as I was in there, I took a pic to share with those who may wonder what's behind the cover. I was impressed with the cleanliness of the interior of the gearbox. Not a bit of swarf anywhere.

Going a bit deeper, I got inside the headstock. Found the source of the noise - bearing at the input side of the spindle shaft. But there's no decernable play and it runs true so I won't be premature in affecting a decision to replace it just yet. I did find that the speed control circuit board which is housed in the same area was contaminated with what appeared to be silver colored metal dust (perhaps the residue of a drilling operation) and because electronic circuits don't like that kind of stuff I did a compressed air cleanup.

UPDATE:

(For those who may need to remove and replace the gearbox cover for future maintenance)

Putting everything back in place requires a bit of adroit manipulation that would have been easier if I had four hands. Setting the feed direction, feed rate and feed/thread gears in their neutral positions and then "eyeballing" the alignment of the operating levers to mesh with the correct gear set worked best for me. I made a wooden block to just fit between the bottom of the gearbox and the tray and slipped it into place to support the cover whilst tipping the cover into place.

Attachments

Last edited: