- Joined

- Jan 28, 2022

- Messages

- 66

so a few years ago I bought a desktop cnc router 3018-SE V2 from FoxAlien

the idea I had got it for was engraving some stuff for friends to upgrade some gifts for them

a few years later I figured, I paid a pretty penny for this thing maybe its about time to get some more use out of it

I have an idea on what I can do with it, need to figure out holding (will likely need to make something)

and where to get the base stock from

my ? for people who have used these what where you able to cut and how deep? (looking at brass or Aluminum as the stock)

are there any cheap upgrades that help with them?

are there any not costly bits for doing deeper engravings in metal something like 1-1.5mm deep

and what programs are beginner friendly as I was barely able to engrave line art and some text with the program it came with

stock photo of the CNC I have, and I do have that extra control panel

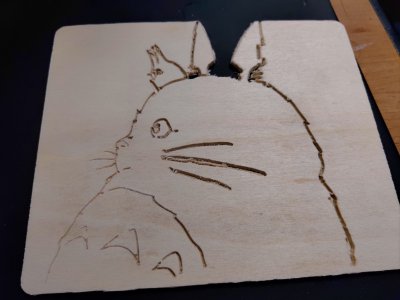

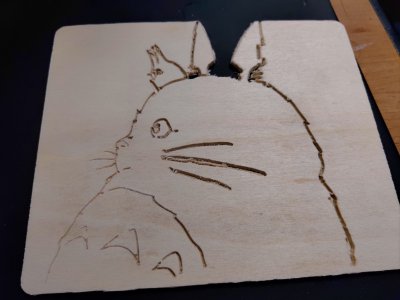

one of my engravings, seems I did not take almost any photos of the others

the idea I had got it for was engraving some stuff for friends to upgrade some gifts for them

a few years later I figured, I paid a pretty penny for this thing maybe its about time to get some more use out of it

I have an idea on what I can do with it, need to figure out holding (will likely need to make something)

and where to get the base stock from

my ? for people who have used these what where you able to cut and how deep? (looking at brass or Aluminum as the stock)

are there any cheap upgrades that help with them?

are there any not costly bits for doing deeper engravings in metal something like 1-1.5mm deep

and what programs are beginner friendly as I was barely able to engrave line art and some text with the program it came with

stock photo of the CNC I have, and I do have that extra control panel

one of my engravings, seems I did not take almost any photos of the others

Last edited:

![51Wh3r3EVPL._SL1500_[1].jpg 51Wh3r3EVPL._SL1500_[1].jpg](https://www.hobby-machinist.com/data/attachments/408/408996-1f25689bd014c625cdf1e948b67308c4.jpg)