- Joined

- Nov 5, 2016

- Messages

- 1,419

This just came out and is a great beginning aluminum TIG welding "how to".

Have fun!

Ted

Have fun!

Ted

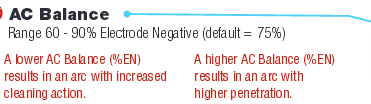

I also don't remember you saying what you had your balance control set at??? Maybe you did and I missed it. 30% positive and 70% negative is a good place to start. You want good cleaning action without burning your tungsten up.

Yes, Ted I know about balance but it was not clear as far as how to set the welder up properly for 30/70. The main difficulty I have is

with the instructions and how to apply them. I need to learn how to set the balance with this machine.

AC Balance Control

10-90% of EP

Selects the percent of Electrode Positive (EP) used during AC welding to provide cleaning.

This divides the amount of time that the AC cycle is in Electrode Positive or Electrode

Negative during one full AC cycle. It controls the amount of cleaning and penetration via

a ratio to achieve the best balance while welding on AC. When the control knob is rotated

left, more Electrode Negative is present and more penetration will be achieved. When

the control knob is rotated right, more Electrode Positive is present and more cleaning

(cathodic etching) will be achieved.

and to top it off it all being a Norwegian,

and to top it off it all being a Norwegian,