- Joined

- Jan 22, 2022

- Messages

- 128

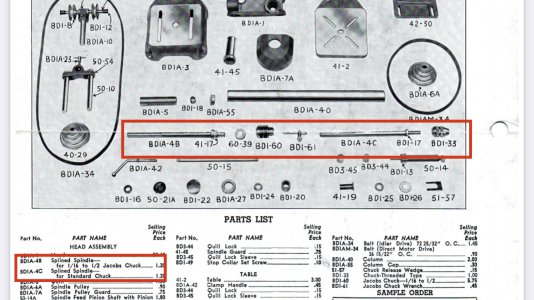

Hey guys. I picked up this drill press on Facebook yesterday for $10. Saved it from the scrap yard. From the best I can tell by google image search it’s a Dunlap or Companion. Can anyone confirm this?

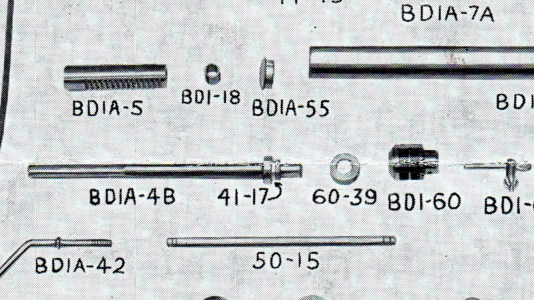

I have a spare motor that I’m going to place on it. 1725 rpm. Any leads on a new quill spring cover? That’s about all that’s keeping me from running it.

Also, does anyone know anything about replacement chucks? As in what type? Is this a weird threaded on type of chuck???

The plan is to get it working well and repainted. And I’m seriously considering adding a third pulley for slow speeds.

Thanks guys!

I have a spare motor that I’m going to place on it. 1725 rpm. Any leads on a new quill spring cover? That’s about all that’s keeping me from running it.

Also, does anyone know anything about replacement chucks? As in what type? Is this a weird threaded on type of chuck???

The plan is to get it working well and repainted. And I’m seriously considering adding a third pulley for slow speeds.

Thanks guys!