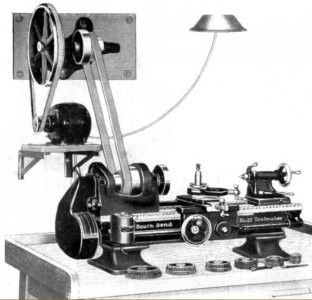

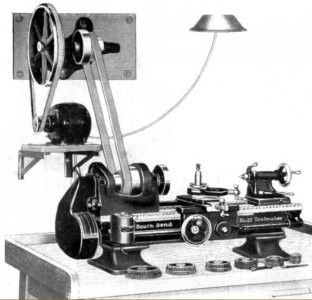

I am hoping to wall mount my lathe motor and countershaft, something on the order of this:

My questions are about tensioning both the motor belt and the flat belt.

I was thinking of hinging the motor shelf so the motor belt would tension under gravity. I don't love this solution, but it would be easy enough to accomplish. Another idea I had was to bolt the motor to angle iron mounted to the wall. Maybe add a spring belt tensioner, although I don't know where to look for one that isn't an auto part.

On the other hand, I need to be able to remove and re-tension the flat belt in order to change speeds. I've seen pictures of what looks to be a handle system, but the pictures all lacked any accompanying explanation.

Ideas? Best practices?

Thanks in advance.

My questions are about tensioning both the motor belt and the flat belt.

I was thinking of hinging the motor shelf so the motor belt would tension under gravity. I don't love this solution, but it would be easy enough to accomplish. Another idea I had was to bolt the motor to angle iron mounted to the wall. Maybe add a spring belt tensioner, although I don't know where to look for one that isn't an auto part.

On the other hand, I need to be able to remove and re-tension the flat belt in order to change speeds. I've seen pictures of what looks to be a handle system, but the pictures all lacked any accompanying explanation.

Ideas? Best practices?

Thanks in advance.

Last edited: