- Joined

- Dec 30, 2017

- Messages

- 117

Picked up a (well-loved, by all appearances. Looks pretty good, used, but taken care of) Skinner four-jaw six inch off the fleabay! Hopefully everything works out well when I get it!

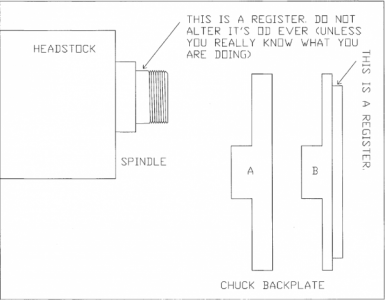

Comes with a backplate that should fit. If I understand correctly, I'll have to screw the backplate onto the spindle and machine it so everything is concentric/true and then put the chuck on, right?

Comes with a backplate that should fit. If I understand correctly, I'll have to screw the backplate onto the spindle and machine it so everything is concentric/true and then put the chuck on, right?