- Joined

- Sep 20, 2012

- Messages

- 560

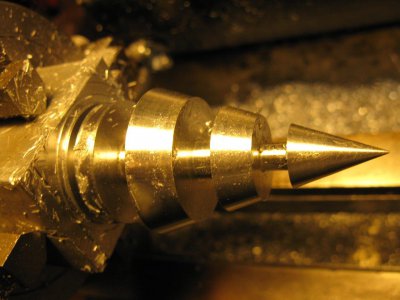

Having decided the original tin oil filler/breather cap looked a too bit cheap on top of the ally rocker cover I set about making a new one, took my time and managed to plan the sequence of operations properly for once

Quite pleased with the look now...

Bernard

PS this is the vehicle the engine is for, just a bit of fun....:biggrin: https://www.facebook.com/Rugged.Robin.tracked?ref=hl

Quite pleased with the look now...

Bernard

PS this is the vehicle the engine is for, just a bit of fun....:biggrin: https://www.facebook.com/Rugged.Robin.tracked?ref=hl

Last edited: