Yesterday was a busy one for me, a friend came by with a project for me. He wanted to replace the bolt on his high pressure air rifle. The original bolt is pot cast metal.

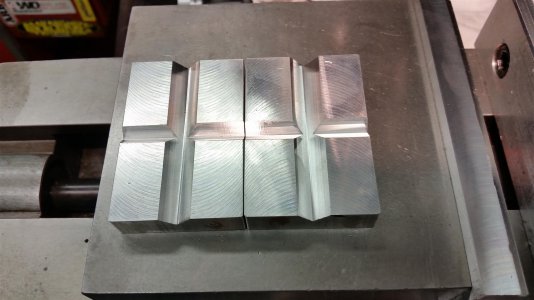

For the replacement bolt, started with a Hex brass rod, turned down a shank and allowed the knob enough material to turn with the ball turner, but when we look at how neat the hex would look like, we left it at that, proceeded to single point the other end with 1/4x20 thread and called it good.

The barrel where the handle screws into was turned from the same hex material. The hole that goes over the charging rod inside the rifle was drilled and bored to .318 at .375 deep. Copied the size from original bolt. The Kaiser Thin Bit micro bore with miniature Trigon came in real handy.

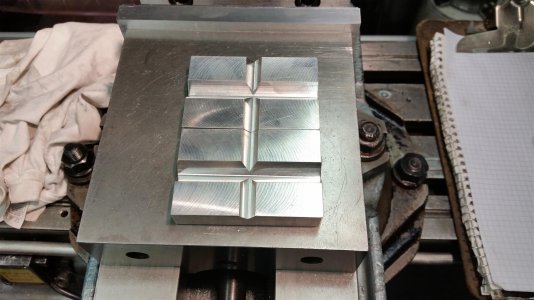

Set up the barrel part on the mill, drilled and threaded the connecting hole for the handle. Counter sunk the hole with an end mill for the shaft would sit in. The locking set screw in the barrel part of the bolt, not shown in the picture, is close to 5 degrees from the centerline of the knob shaft, drilled and tapped it with 10-32

Learned a good lesson. The first piece I turned for the barrel part of the bolt was scrapped. I was measuring with the digital micrometer with the zero re-setted at the wrong place, and NOT verified/checked on the standard gauge before I started the work.