Ha I never thought about using an old bolt as stock but thats a good idea Smudge. Depending on the grade of bolt it may hold up better than crs.

I think the pc of scrap I used is actually SS. Wont rust but on the soft side.

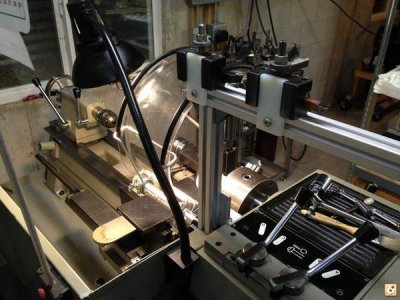

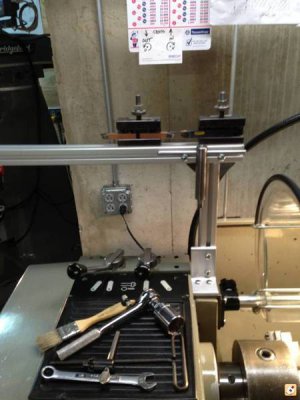

ARM yes lathe is an 11x30 colchester. I always thought it was a rare model but I see lately there are several guys on here who have them.

Guard is made by Flexbar products. Never thought I would like a guard (pita obstruction) but it really doesn't get in the way and flips up quickly for part access. Wouldn't go out and buy one specifically but I got it in a pile of stuff at auction so figured id use it. Really helps with containing chips and spray. Fabbed the mount for it to utilize existing fastener holes in the backsplash guard.

Being off all this week is like heaven.

Spending lots of time puttering down in the man-cave. Emerge only to eat, sleep and occasionally shovel the driveway!!

Today working on a storage rack for the Aloris tool holders.

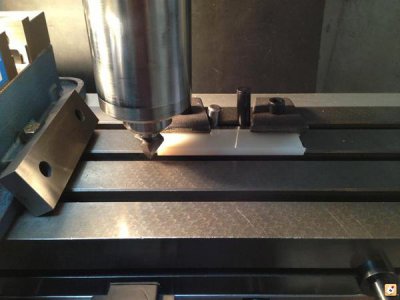

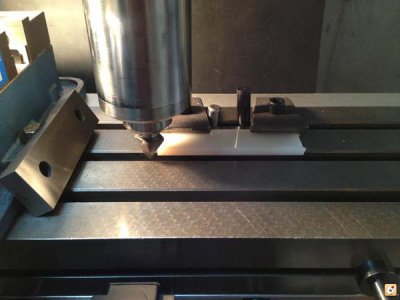

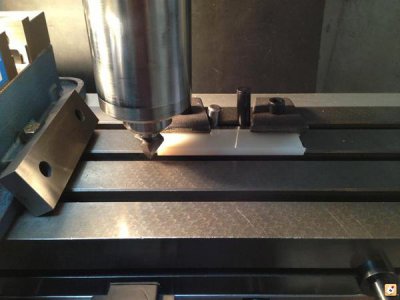

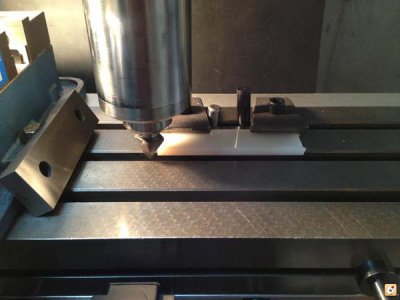

Machining some nylon strips to match the dovetail on the holders. Gonna cut into 2" long sections, drill a hole and mount to the face of some 80/20 type extrusion.

Cant decide if I want the rack in back of the lathe or on the pegboard behind me on the workbench.

Mounting on the lathe will give better access but subject them to being covered with swarf.

What do you guys with QCTPs do for storing you holders?? Id love to see your setups.

Right now i have them on the pegboard on the bench directly behind the lathe. Using extrusion as a shelf w/ fender washers to retain.