-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

- Forums

- THE PROJECTS AREA

- PROJECT OF THE DAY --- WHAT DID YOU DO IN YOUR SHOP TODAY?

- Project of the Day Mega-Thread Archives

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

2015 POTD Thread Archive

- Thread starter jumps4

- Start date

- Joined

- Aug 22, 2012

- Messages

- 4,131

What kind of birds are those?

The birds are Australian Magpies although they are not related to the European Magpies who are members af the Corvid family.

Aussie Magpies are closer related to the Butcher birds.

The one on my knee is the dad, mum is in the middle and child is on the right. Its a family of four and the dad and one of the kids who I assume is also male will come right into the middle of the shop asking for a feed. They are the only ones who will sit on my knee but all four will take food from my hand.

I dont know why it feels so good hand feeding them but it does.

Their warbling song is very melodious and when all four get going it sounds awesome.

In the nesting season some of the males will attack anyone who comes near the nest so it will be interesting this year if they bring their youngsters back.

- Joined

- Feb 8, 2014

- Messages

- 11,145

Re: Pitot tube fabrication

I have never seen a pitot tube with a little flip-up cover like that. Pretty cool, a great idea to keep the wasps and spiders out. What's the design flip-up airspeed?

Well, I guess you won't see this every day: I used the mill, the lathe, and a small metal brake to fabricate a new pitot tube and mount for the plane I'm building. The pitot tube supplies ram air pressure to the airspeed indicator, through a long vinyl hose threaded through the wing. I chose Delrin for the block because it's lighter, and I machined the hose fitting as an integrated feature. All this saves 3-4 ounces off the weight when compared to the "usual" materials. Lower weight = better aircraft performance. A few ounces here and there adds up to a significantly lighter aircraft in the end.

Tom

I have never seen a pitot tube with a little flip-up cover like that. Pretty cool, a great idea to keep the wasps and spiders out. What's the design flip-up airspeed?

Another tidbit - a keeper for retaining the knee elevation crank handle on a Bridgeport. Simple little piece turned on the South Bend. Used the SB to chuck up the elevating shaft for drill and tap to quarter-20.

The keeper allows you to slide the handle/crank away enough to pivot the handle down out of the way, or readjust how the handle is clocked so you can turn/feed the knee up/down with the handle right where you want it. Also, allows the handle to stay where it is - in order for someone to knick the handle, they'd need an allen wrench. Not a lot of effort but keeps the 'casual' borrowers honest.

Ray

The keeper allows you to slide the handle/crank away enough to pivot the handle down out of the way, or readjust how the handle is clocked so you can turn/feed the knee up/down with the handle right where you want it. Also, allows the handle to stay where it is - in order for someone to knick the handle, they'd need an allen wrench. Not a lot of effort but keeps the 'casual' borrowers honest.

Ray

- Joined

- Dec 22, 2012

- Messages

- 328

I have never seen a pitot tube with a little flip-up cover like that. Pretty cool, a great idea to keep the wasps and spiders out. What's the design flip-up airspeed?

Jim, the airspeed activation point is adjustable: The top tab can be bent forward or aft, or weight can be added ahead of the pivot point. In my case, the small rudder on my Sonerai becomes effective at ~40 mph, so I will adjust to 25-30 mph. I like this gadget because I will never have to deal with forgetting to remove the pitot cover, nor will I have to discover a mud dauber has plugged it up.

Tom

Pitot tube fabrication

.... A few ounces here and there adds up to a significantly lighter aircraft in the end.

TomView attachment 94904View attachment 94905

Remember that at lunch!

Ken

- Joined

- Mar 14, 2013

- Messages

- 443

Re: Pitot tube fabrication

I have never seen a pitot tube with a little flip-up cover like that. Pretty cool, a great idea to keep the wasps and spiders out.

The cover is a standard item from aircraft suppliers. I've considered one for my plane, but I'm thinking about using a screen instead... it too will keep the bugs out, and since there's virtually no airflow into the tube it shouldn't affect anything.

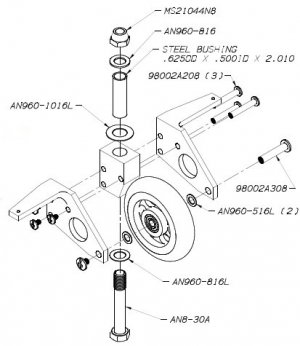

My project today, and for the last few days, was to build a new tailwheel for my plane to replace the junky caster wheel that looked like it belonged on a supermarket cart. Commercial ones were all either out of stock, too heavy, and/or too expensive, so I designed my own. Definitely the most complex shape this noob has yet made, and a bit of a challenge on a mill/drill, but I'm pretty happy with how it came out:

Haven't had much time with the mill other than small projects. Someday I will have it cleaned up , painted and have some tooling to tackle bigger projects.

A friend wanted a brake removed so he can change handguards . For some reason they welded a brake on a 20" barrel ?

So then the wife wanted some hooks for a pinterest project . She is so good about letting me work out in the barn I have to let her play too. She needed four brackets so it was easier to mill all them at once.

Honestly it is sixty five degrees in there.

A friend wanted a brake removed so he can change handguards . For some reason they welded a brake on a 20" barrel ?

So then the wife wanted some hooks for a pinterest project . She is so good about letting me work out in the barn I have to let her play too. She needed four brackets so it was easier to mill all them at once.

Honestly it is sixty five degrees in there.

Last edited:

- Joined

- Nov 9, 2010

- Messages

- 306