- Joined

- Apr 21, 2015

- Messages

- 894

That's awesome. When I start hauling in gear for a photo shoot, after about my 3rd trip someone always asks, "How much do you have?" I usually respond, "I drive a Suburban for a reason."way smaller than my big pro video heads..take up about 10 seats..lol

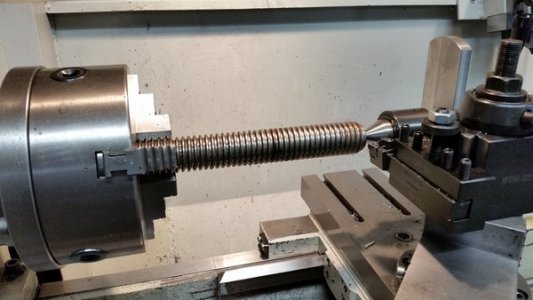

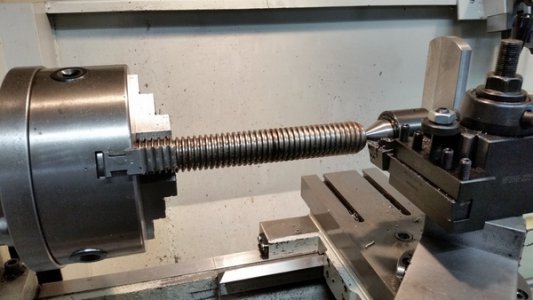

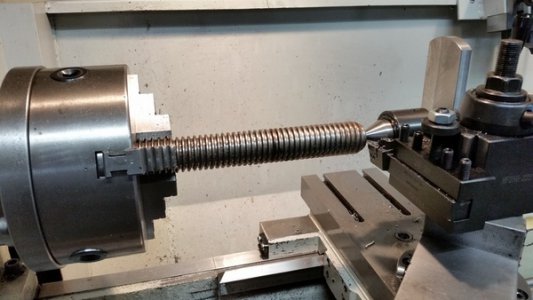

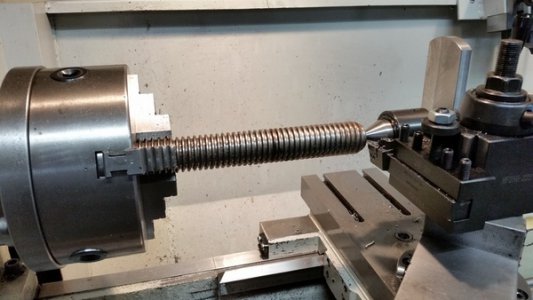

I have always wanted a geared head (like a Manfrotto 405 or similar) for architectural and product work (I mostly do automotive these days, but used to do real estate and hotels), but they're so expensive for such specific use that I've never justified them and just use a ball head for almost everything. Since getting interested in machining I've wondered if I could figure out how to make one, but that is a LONG way down the road, limited by both my minimal equipment and skills.