- Joined

- Jun 15, 2013

- Messages

- 1,199

Well there are some good welds there. But the one on top although it looks pretty and will hold fine for it's intended use I'm sure. Should be tightened up. It would most likely get rejected do the lack of tie in at the toes. It looks more like a roll of tack than a continues weld. All them valleys make great places for cracks to form. A bend test would more than likely break the weld at these points. Just my opinion though based on what I have seen inspectors reject and failed test plate I have seen. Not mine of course.View attachment 121331 Sorry mark, he's not an instructor, but just Google ztfab, that will get some pics and maybe one video or so, but his website should be at the top, zero tolerance fabrication, here's one image

Not every picture that shows up on Google are his welds only the really nice ones

Well there are some good welds there. But the one on top although it looks pretty and will hold fine for it's intended use I'm sure. Should be tightened up. It would most likely get rejected do the lack of tie in at the toes. It looks more like a roll of tack than a continues weld. All them valleys make great places for cracks to form. A bend test would more than likely break the weld at these points. Just my opinion though based on what I have seen inspectors reject and failed test plate I have seen. Not mine of course.

Mark

Johnny ,

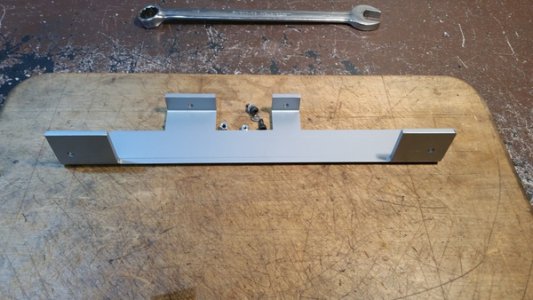

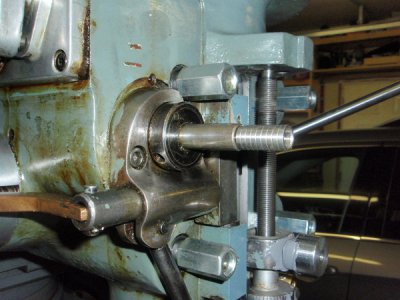

If you rotate the sleeve as shown in the bottom picture so the slot is between 09:45 hrs and 09:50 hrs the slot will be easier to close up giving you a much greater grip as well as keeping excessive strain off the clamping screws

I had similar problems to you and made a sleeve up too but found the tool rotated a bit whilst I was boring a 2 " hole .

Once I realised why it had turned and I'd reset the clamping slot it tightened up very easily and very effectively .

Lol omg mark, that's funny you mention the bend test, cause his welds pass with flying colors, there are a ton of people that bawk at the appearance of the welds and just haven't a clue that they are just as strong as "proper" mig beads, it's technique, not trigger stop trigger stop, and intended purpose? Really? They are in a desert race truck flying through the air at 80+mph, 3ft whoops, weighing in at around 3000lbs or more just totally stressing that vehicle to the max, what more of an invitation for Cracks and abuse do you need to become a believer that those are as sound of welds there could ever be??? You must be an ol timer, stuck in your ways lol, damn kids, those welds are gonna break on the first mile down the track hahahahahaha

I can assure you those are continuous welds, not tacks, and the one corner where there are 3 joints, he welds like that one some corners for a reason, whether it's just aesthetics for instance, having all the ripples facing a certain direction or maybe it's heat control to control warping, idk the guy is a master welder, but I'm out, I can see your not gonna be made to think those welds are of the best there is cause it's new, it's not the old mig pattern that all the ol timers grew up on, and we're taught that way the right way, and the only way

I purchased this case from B&H when i ordered the camera. The case I ordered was a Pelican 1500.

http://www.bhphotovideo.com/c/product/40657-REG/Pelican_1500_000_110_1500_Case_with_Foam.html