If you're ever in Salt Lake City and you have a way to carry home significant weight, make sure you stop by NPS (

www.npsstore.com) for incredible deals. They have an industrial side and a retail side (food, clothing, kitchenware, etc.). Much of their stuff is refused freight, store returns, etc. I buy fasteners of all sorts on the industrial side for 50 cents per pound. Huge, pleated, high quality furnace filters for a shop air cleaner or spray booth I hope to make some day for $1 each. Lead acid batteries for 70 cents per pound. This is a huge warehouse (Costco size plus) in an industrial neighborhood, with a couple dozen bays in the loading dock. You could spend a week there and still feel like you hadn't seen everything yet.

They have raw materials as well. That's why I went today. There's no telling what the selection will be before I go (and it's about 35 minutes each way), but it's usually worth it. If the labeling can be believed this huge chunk of steel (5"? 6"? round) is 15 pounds of A2.

I wanted to buy it but I had told my wife (who was with me) that I would only spend $20 on materials and I had higher priorities. And I don't have any way of cutting that except the lathe at this point. I actually only bought a fraction of what would have been worth it to buy, but I know there will be more next time.

I should have taken a picture of the whole department. Roughly 3/8" thick, 12"x18" plates of apparently pure copper for $90 each. Dozens of 8' lengths of 316 SS 3" round stock for $40 each (and everything in the department at least 8' long is currently on sale 40% off). One chunk of stainless I could not have lifted if my life depended on it for $150.

Anyway, it's a very cool store. They have a good eBay store as well, but the prices are usually better in person (because the only stuff that goes online is 100% identifiable, retail or commercial).

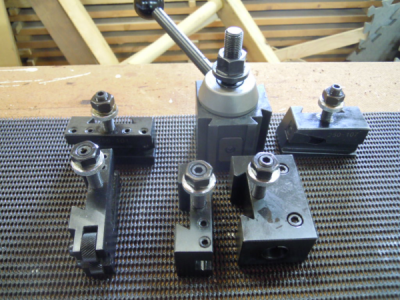

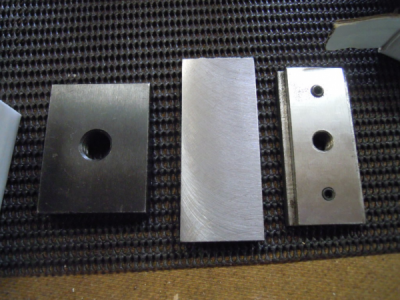

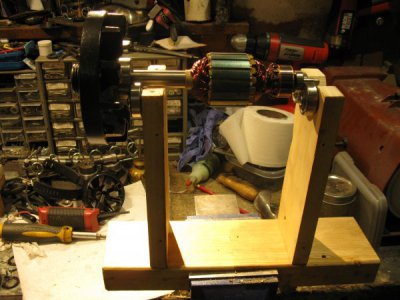

Here's what I bought today, plus the 12" Nicholson files (one single, one double cut half round mill, and there's a matching flat bastard around here somewhere) I got last time for $2 each. (They have pallets of those files, btw, and any files 10" and shorter are only $1. All Nicholsons, Stanley's, and Stihl at this point.

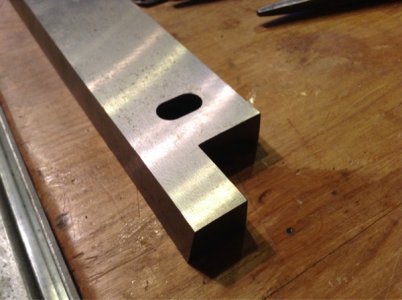

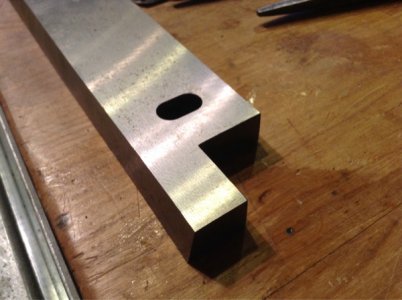

According to my spark tests, comparing known samples, the large round stock is a medium carbon steel (1040-ish), the short, bright round stock is chromoly (4140?), the other round stock and all the square stock is high carbon, and that big, BEAUTIFUL blade on the bottom is unquestionably tool steel. I knew that much just by the form, but it was fun to see the sparks and show my wife why I was so excited about it. I'm going to send that with my brother to his work (Silencerco, for those who are familiar) to test it so I know exactly what it is.

Did I mention that all non-stainless is $0.50/pound? Everything in that group shot except the two long files was $20.xx with tax. I didn't spend any time this evening in the shop (except the spark tests), but it was still a very productive day for my little shop.