- Joined

- May 6, 2016

- Messages

- 20

Here is the Sunday job, just helping out a friend in his shop. Pretty cool parts that I made for him before.

My brother works with a guy who spent a ton of money on a turbocharger and other silly things for his jeep. I just don't understand that. In what situation does a jeep benefit from turbocharging?He needs a drive shaft like I saw in AK while I was there, We had some guys that kept twisting them off, and one company made one that they guaranteed not to brake or twist. I bet some of them could still do it. These guys would put more motor in old Land Cursers and tires that were taller that the finders on my car, and then just see what they could go through, Towing them out of the bush was often fun.

Some people just have more money than sense.

I'm sure most of the Canadian guys have heard, but the news may not have reached many in the US. We've had a massive wild fire up in the oil sands region of northern Alberta. They had to evacuate the city of Fort McMurray, and there are currently 90,000 people living in shelters in various parts of our province. The city is still under a mandatory evacuation order, and we haven't had any really reliable reports on how much damage was done. Yes, the fire did sweep right through the city. The outpouring of support for the refugees has been enormous. I gave some cash, but wanted to do more. Hummm....what to do.....

I'm a moderator on a fairly large gun owners website here in Canada. I got permission from the administrators to do a little fund raising project. The guys on the site have been on me for a few years to make something called a "challenge coin" that would be excusive to the fiercely loyal members on our site. Well....I've never made a coin before. Even better...how can I make a coin that would be exclusive to our site (short form letters of the name are GOC) and make it something shooting related ?

Well....let's put a target with some shots in it on one side....the name of the website/group on the other....and let's make it out of a bullet !!! Heck yeah !!! After much failure, I finally just took a diamond bit and engraved the letters free hand on one side of the die. The other side with the target was easy in the lathe...then I used a center drill in the mill to put a few dimples in it for the bullet hits. They turned out a little rougher than I'd have liked, but from getting off on Friday night with nothing but a fund raising idea, to pressing coins out of bullets by Saturday lunch time...not too bad. Everybody who contributed anything is getting a coin mailed to them. I've raised $780 for the fire relief fund so far ! Yay !Heres a few pics and a video.

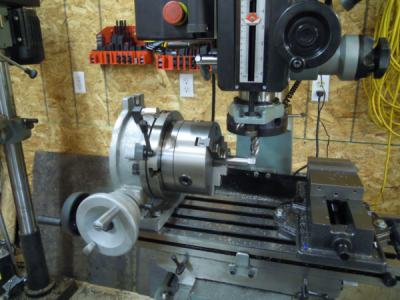

I also got prices for some of the pins and bushings I will need to do the repair and that came to around $500. So I decided to do the best I can with what I have. I have already made one of the tapered and threaded pins and have now completed another plus 2 tapered bushings to fit into the worn end pin receivers. Now I'm in the process of making a boring setup for the 2 ears, following a thread on this forum. I found a piece of 1" cold roll steel but it was a bit too short. So I made an extension that will thread in to the end of the 1" cold roll and also has a 1/2" hex head for the Hole Hawg drill that I will use to turn the boring bar. I did'nt have a chuck for my new rotary table so I ran into the City and picked one up. I love having the rotary table and the chuck makes it even better. Here are the pics so far.

I also got prices for some of the pins and bushings I will need to do the repair and that came to around $500. So I decided to do the best I can with what I have. I have already made one of the tapered and threaded pins and have now completed another plus 2 tapered bushings to fit into the worn end pin receivers. Now I'm in the process of making a boring setup for the 2 ears, following a thread on this forum. I found a piece of 1" cold roll steel but it was a bit too short. So I made an extension that will thread in to the end of the 1" cold roll and also has a 1/2" hex head for the Hole Hawg drill that I will use to turn the boring bar. I did'nt have a chuck for my new rotary table so I ran into the City and picked one up. I love having the rotary table and the chuck makes it even better. Here are the pics so far.