- Joined

- Dec 27, 2014

- Messages

- 4,056

duplicate with errors

Last edited:

Paco,

I really like that cable activated E-Stop on the plate roller.

Is that (specifically the cable type) common in those types of machines or did you and/or Mark come up with it?

Either way, I think it's very clever, simple, cheap and so smart. Downright elegant, IMO.

Thanks,

That cable set up came from the manufacturer. Mark incorporated a mushroom E-stop switch to the same system as well as a power button with pilot light and a E-stop trip light.

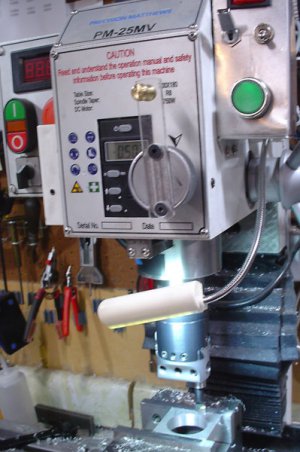

The box has nice labels now and a added green pilot light

This is a photo of Mark's upgrade control system.

The original was a mess with no 24v controls.

The only original components are the transformer and fuse block, everything else was designed and squeezed into place by "The Wizard " Mksj.

A good day all in all.

Thanks for looking.

Turn and burn!

Paco

Thanks Mike,

Nice work on your stock rack. Using as much vertical real estate as possible is a great idea. The TIG welds look great too.