Ok, here's my pathetic project. I didn't need to use a forklift. (Good thing because I don't have one)

What it lacks in skillful machining and complexity, it more than makes up in usefulness.

It's a bracket to hold my golf GPS to the windshield post on a golf cart.

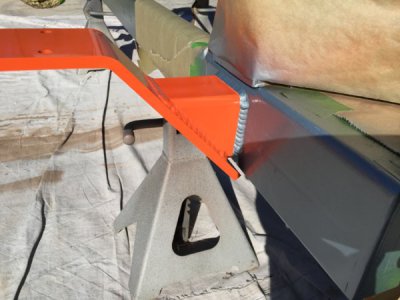

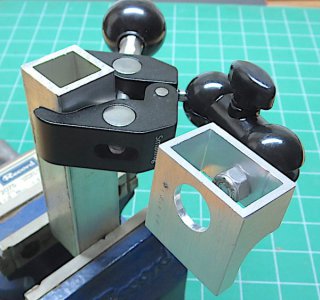

The clamp and ball joint arm are photographic accessories.

The aluminum thing (not the black stuff) is what I made.

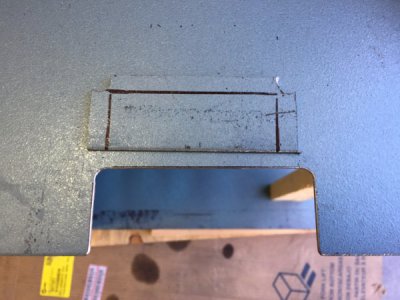

The bracket provides something for the belt clamp that came with the GPS to hold on to.

View attachment 242698

The big hole is so I can access the nut with a nut driver.

I also modified the clamp by replacing the sliding T-handle with a ball. It is just epoxied on.

View attachment 242699

View attachment 242697

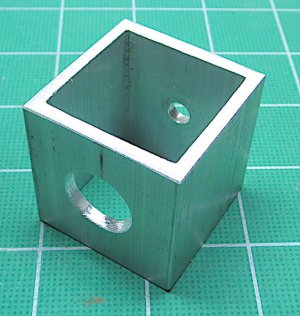

The is the first part I made for proof of concept (to see if it works). I used it yesterday and it worked great.

Also, at the time I made it, I didn't have any 1.5" x 1" Aluminum tube. I just got that material today.

I did a little extra shaping on the final version to lighten it and make it look spiffy.

View attachment 242700