-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1940 South Bend 9A

- Thread starter Bailey

- Start date

- Joined

- Jun 22, 2012

- Messages

- 1,552

Bailey, got your pm, wrenches will be coming at you!

Greg

Greg

Bailey, got your pm, wrenches will be coming at you!

Greg

Thanks Greg, stonehands if helping me get some parts and I'll be sure to thank him also.

I don't think I would paint that machine. Clean it up and cover it with a light coat of oil and it would look great. Just my preference. Keep the pics coming.

Chuck

Chuck,

I considered not painting but with the humidity here in SELA, the lack of paint on many areas

and since I had the machine completely apart I opted for a paint job.

If I did it again I would use a rattlecan and not have brushed it, spray dries fairly quickly but enamel with a brush took days to dry.

I have it about done with the exception of the compound and it will get a coat tomorrow night.

Bailey

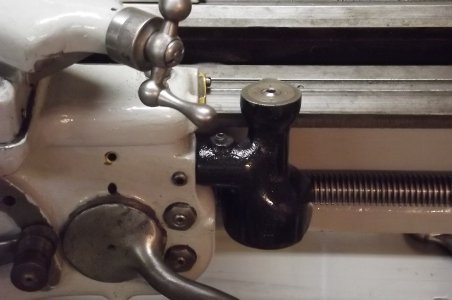

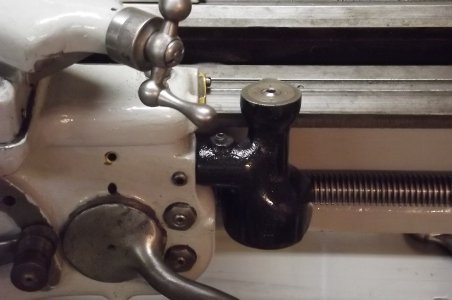

A few pics of the machine after cleaning, new wicks and a coat of paint.

My main concern was to put the machine back into service and my attention to detail will never compare

to some of the fine work of other members I have seen on this forum.

Some parts were replaced, compound, new nuts for compound and cross slide, backgear, a missing gear cover.

Socket head screws replaced the slotted screws when possible.

The bed has some good nicks in it near the headstock and the high spots were removed.

Now its time to start tuning and tooling it up.

I have got a Phase 2 QCTP import to replace the original lantern type TP and put a new 5" 3 jaw to replace the old

Union 6" that came with the machine and hope to have an old 4 jaw 6" repaired in the next few days.

Bailey

My main concern was to put the machine back into service and my attention to detail will never compare

to some of the fine work of other members I have seen on this forum.

Some parts were replaced, compound, new nuts for compound and cross slide, backgear, a missing gear cover.

Socket head screws replaced the slotted screws when possible.

The bed has some good nicks in it near the headstock and the high spots were removed.

Now its time to start tuning and tooling it up.

I have got a Phase 2 QCTP import to replace the original lantern type TP and put a new 5" 3 jaw to replace the old

Union 6" that came with the machine and hope to have an old 4 jaw 6" repaired in the next few days.

Bailey

Last edited:

- Joined

- Jun 22, 2012

- Messages

- 1,552

Man she looks great! I would run that serpentine belt with the grooves down though. :thumbsup:

Man she looks great! I would run that serpentine belt with the grooves down though. :thumbsup:

Thanks Greg,

I thought I would get a bit more surface area by inverting the belt. Haven't noticed any slippage yet and will keep your suggestion

in mind. Had a little issue with the countershaft slinging oil on the belt at first, that was my fault for over oiling. I am going to put

a fiber washer on the left side of the countershaft also.

Has been a enjoyable project and helped me appreciate the quality and workmanship of the older machines.

Bailey

- Joined

- Jun 22, 2012

- Messages

- 1,552

Sorry for the delay but the wrenches should go out today, got em boxed and ready to ship.

Very nice job on the lathe. I would also suggest flipping the belt, slippage can be a great thing when you accidentally leave the back gear engaged or crash something? I have the same belt and it has never slipped under cutting loads but it has saved me more than once when I engaged the back gear to hand tap a hole and then turned it on without disengaging.

Thanks Shawn,

I have had some walk in the belt and made several adjustments nothing severe but the belt still walks toward the left side of the cs and the belt on the spindle

stays in the location it is set at when I tension the belt.

Turning the belt over to the groove side may help training also, I'll try that tomorrow nite.

I noticed that you also have a SB9, what type of dead center do you use on your tailstock?

Mine will not eject anything less than 4 1/4" in length. I thought the Shars 4 5/16" would do the trick but the taper doesn't start for the first 1.5" duh.

I don't want to say what I have done to correct this on a machinist forum but it involves JB Weld and a short steel plug on the end of my center.

Bailey

- - - Updated - - -

Sorry for the delay but the wrenches should go out today, got em boxed and ready to ship.

Many thanks Greg,

- Joined

- Dec 25, 2011

- Messages

- 10,511

I had a similar ejection problem (although it wasn't on a 9A). I drilled and tapped the small end 3/8"-16 and installed a short spacer with a socket head flat head screw after determining required spacer length with just the screw.

Robert D.

Robert D.