Had been searching for an older SB9 or 10, found a 9A that was listed on this forum.

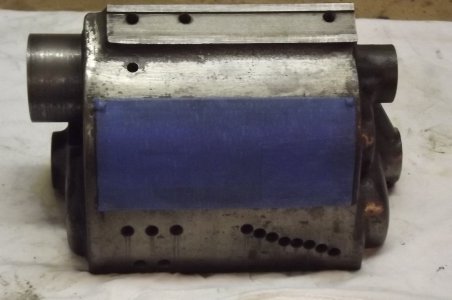

Received the machine last month and have taken it apart, stripped what paint was left and have started

repaint, cleaning and putting it back together. Bought the wicks and repair book.

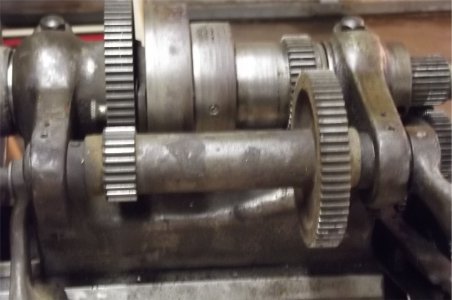

Have completed the QCGB and Apron assemblies, remounted the headstock/spindle to the bed and will start on it next.

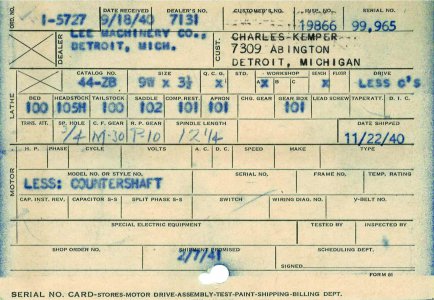

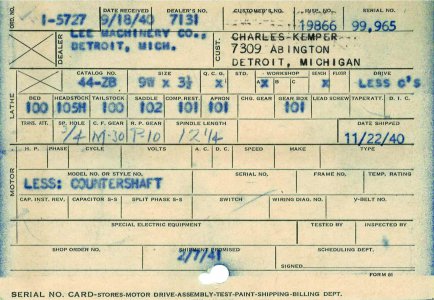

After receiving the unit I ordered the SN ID from Grizz/SB.

It is noted on the original card that the unit came without the countershaft assy.

My guess was that it was a replacement unit or that it went to a shop with a central drive unit for multiple machines.

Any other possibilities?

I did get a countershaft with the machine that has been added during the last 73 years.

Will post more pictures as work progresses.

Regards

Received the machine last month and have taken it apart, stripped what paint was left and have started

repaint, cleaning and putting it back together. Bought the wicks and repair book.

Have completed the QCGB and Apron assemblies, remounted the headstock/spindle to the bed and will start on it next.

After receiving the unit I ordered the SN ID from Grizz/SB.

It is noted on the original card that the unit came without the countershaft assy.

My guess was that it was a replacement unit or that it went to a shop with a central drive unit for multiple machines.

Any other possibilities?

I did get a countershaft with the machine that has been added during the last 73 years.

Will post more pictures as work progresses.

Regards