-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

- Forums

- THE PROJECTS AREA

- PROJECT OF THE DAY --- WHAT DID YOU DO IN YOUR SHOP TODAY?

- Project of the Day Mega-Thread Archives

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

2015 POTD Thread Archive

- Thread starter jumps4

- Start date

- Joined

- Feb 24, 2015

- Messages

- 1,382

Not exactly my post, David. I started a thread called "stock diameter for knurling tools" about a week ago and there are some good links to knurling calculators. Will supplied a link to a previous thread that covered the subject, and there are some new discussions in my thread.

http://www.hobby-machinist.com/threads/stock-diameter-for-knurling-tools.36517/

Will's reply is the second post and just follow his link to some various diameter calculators and more discussion.

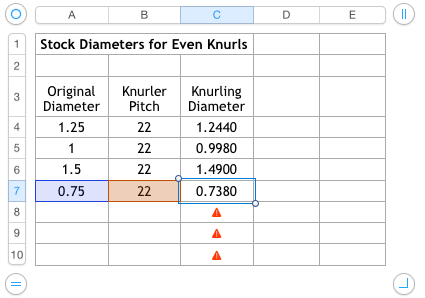

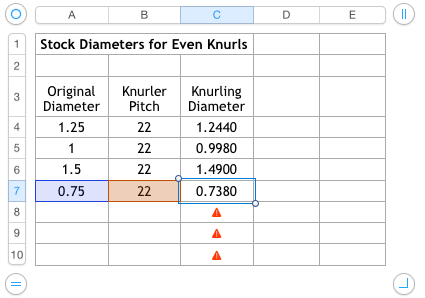

I found a link there to a calculator at Little Machine Shop.com, where I found a spreadsheet I could download that will calculate diameters for knurling. I use a Mac, so many of the others wouldn't work for me. I was able to install "Numbers" (Mac Excell) on my iPhone and iPad and can run the spreadsheet with them out in the shop.

The spreadsheet looks like this (screen shot). Just copy the first line and paste it in successive lines, and type in your values in the first two boxes and it will calculate a knurling diameter.

http://www.hobby-machinist.com/threads/stock-diameter-for-knurling-tools.36517/

Will's reply is the second post and just follow his link to some various diameter calculators and more discussion.

I found a link there to a calculator at Little Machine Shop.com, where I found a spreadsheet I could download that will calculate diameters for knurling. I use a Mac, so many of the others wouldn't work for me. I was able to install "Numbers" (Mac Excell) on my iPhone and iPad and can run the spreadsheet with them out in the shop.

The spreadsheet looks like this (screen shot). Just copy the first line and paste it in successive lines, and type in your values in the first two boxes and it will calculate a knurling diameter.

A friend asked me to make a roll bar clamp for his Can Am Commander so I made him three. They are 3/4" thick and 4" long. The hole is bored 2" to fit the roll bar tube. The flat bottom piece will be drilled and tapped for an antenna.

Tom S

View attachment 106543

Nice job. A clean design your friend should be happy. How thick was the spacer used for the gap?

Nice job. A clean design your friend should be happy. How thick was the spacer used for the gap?

I didn't use a spacer. After boring the hole and before profiling the perimeter I set up and milled about .010" off the horizontal joint. Same result just another way to get there.

Tom S

Those look great, Tom.

Thanks. All the machining steps, except the perimeter, were done in my manual mill. I made a stub .005" larger than the bore, bolted it to my CNC mill table, and profiled the perimeter. Worked great. I'm looking for any excuse to CNC parts.

Tom S

looks like they would also be a good for holding a light bar on a roll cage.

They could. I added 1/4" to the flat cross section to beef them up.

Tom S

- Joined

- Feb 24, 2015

- Messages

- 1,382

I'm looking for any excuse to CNC parts.

Tom S

I would too, if I had a CNC mill.