- Joined

- Sep 26, 2013

- Messages

- 408

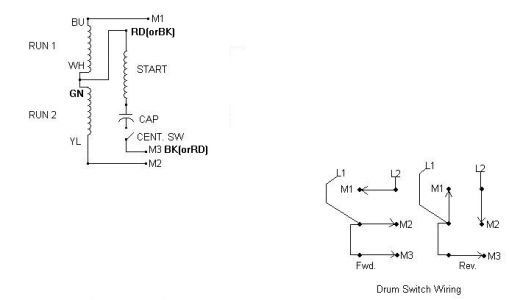

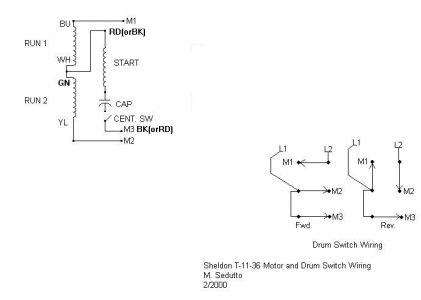

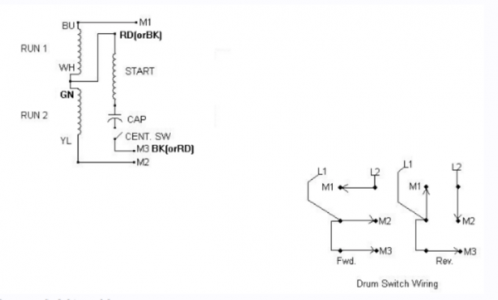

Damn that magic smoke!! Think I fried the motor(damn again). I turned the motor on expecting to here a pleasant humming, sounded like a cross between buzzing and a grinding, hit the reverse position and the motor did reverse, turned it off, maybe ran for 10 seconds, smelled hot and motor case was hot to the touch, not warm, hot. Thought about this for a minute, removed belt from motor pulley to see if the noise might be bearing but really doubted it. Turned motor on again, maybe 5 seconds and there it was, magic smoke #%*^+!!!

I'm bummed not because I'll probably need a new motor(I'm still extremely happy with lucking into the mill) but because I screwed up the oem motor, I'm kinda sentimental about old machinery.

So take a look and let me know what you think. Live and learn, etc., etc., etc. On the plus side I was thinking of getting a DC motor sometime in the future for variable speed and better torque, looks like the future may be now!

Brian

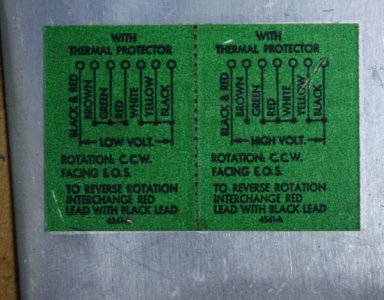

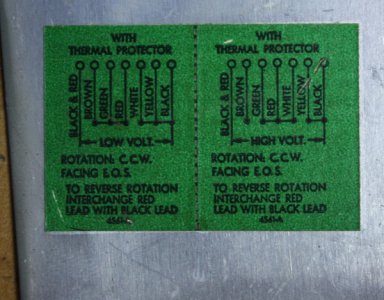

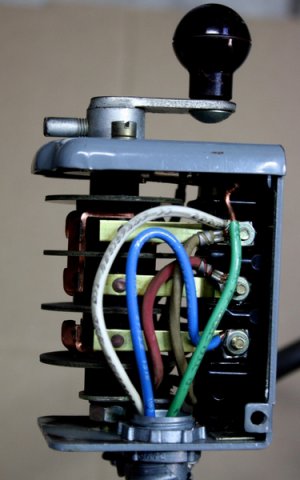

As wired for 120, blue is the hot leg, white is neutral( before I rewired for 240 and before the magic started)

as I wired for 240, the white with the black tape at the bottom is one hot leg, the black hot leg replaced the white neutral, wasn't thinking when I did this(obviously), just replaced the wires where they were before, after the fact I see both hot legs are on the same side so is that the f#*k up?

Should the black leg have gone on this side somewhere(he asks belatedly)?

I'm bummed not because I'll probably need a new motor(I'm still extremely happy with lucking into the mill) but because I screwed up the oem motor, I'm kinda sentimental about old machinery.

So take a look and let me know what you think. Live and learn, etc., etc., etc. On the plus side I was thinking of getting a DC motor sometime in the future for variable speed and better torque, looks like the future may be now!

Brian

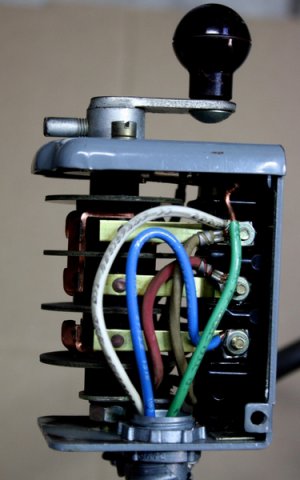

As wired for 120, blue is the hot leg, white is neutral( before I rewired for 240 and before the magic started)

as I wired for 240, the white with the black tape at the bottom is one hot leg, the black hot leg replaced the white neutral, wasn't thinking when I did this(obviously), just replaced the wires where they were before, after the fact I see both hot legs are on the same side so is that the f#*k up?

Should the black leg have gone on this side somewhere(he asks belatedly)?

Last edited: