You reminded me to check my records, as I, too, am waiting for a Zambuto mirror, which is due this December if he sticks to his delivery schedule. As for where I'm going to store the scope once it's complete, that's a different story!

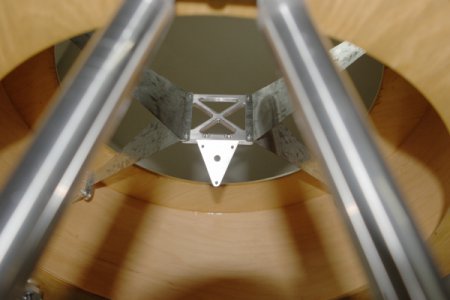

Anyway, how are you planning to attach the secondary to its support? I real of all kinds of methods, and most work, and a few don't! I haven't decided on the spider design. At first I was heading down the wire rabbit hole but may end up doing very much the same as you for rigidity and simplicity.

Regarding the ball ends on your trusses, did you fabricate them or buy knobs from McMaster? Of the latter, are they aluminum?

When complete, mine will be a 16" f/4.3 6-truss design. The details of its aesthetics is still up in the air, but will probably end up more functional than artistic. I don't plan on transporting it much and want it stout and not losing collimation too easily.