B

Bill Gruby

Forum Guest

Register Today

Wowsers!!! That's quite the "restoration" ... "trashed" seems much too mild a word for the 3D jigsaw puzzle condition of the original! :man:

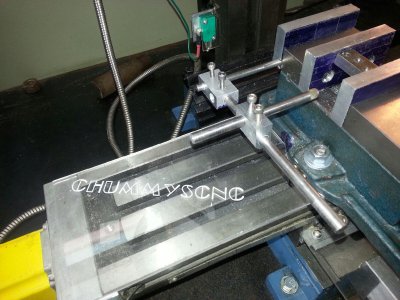

Hi SHAWNThe quill lock on my Clausing 8520 is just a bolt and I was always reaching for the wrench, so I turned out a new lock with a lever. Should have done this a long time ago.

View attachment 61746

Shawn