- Joined

- Feb 7, 2011

- Messages

- 5,039

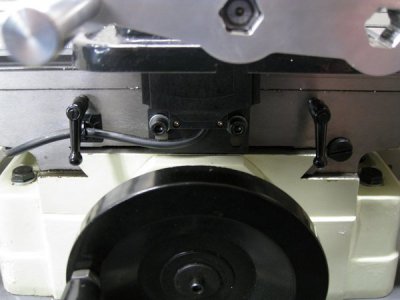

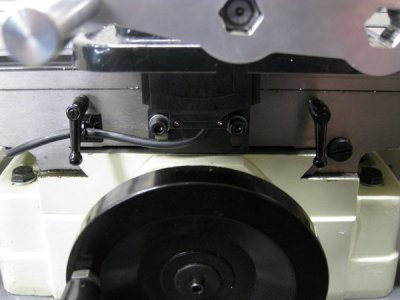

This is what I use on my tailstock. http://www.grizzly.com/products/Quick-Clamp-Lever-1-4-20-Male-Long/G7325

Darkzero,

In your second photo above, are those dog point setscrews or ???, that you modified to work with the clamping levers.

Very clean and clever solution.

Thanks for posting.

Thanks. Yes, they are dog point set screws or aka extended point. The thread I needed for my locks are M8 but the short handle length that I needed were only available with M6 threads. So I rethreaded the ends of the M8 set screws to M6 & permanently screwed them into the the handles. They've been working great & none have ever came loose.

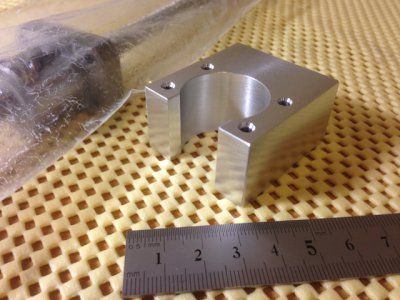

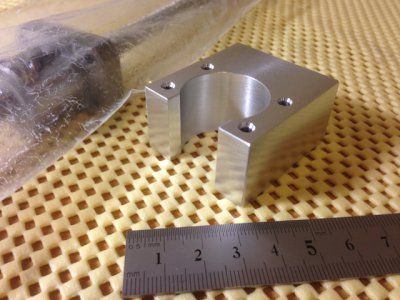

I just need to clean them up now

I just need to clean them up now

Having lived in Lafayette Louisiana, I approve of this recipe