- Joined

- Jun 15, 2013

- Messages

- 1,199

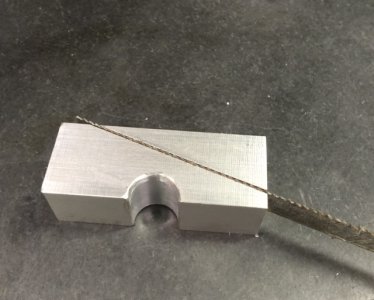

my mill showed up with a little with wood jammed in the center of the X screw, I tossed an indicator on the screw and read .050" runout, she be bent. But being that it was used the shipping company did nothing for me, although clearly it had been bumped into another crate or whatever, it didn't hurt anything else that I could tell, BUT I don't know if the shock could have damaged the Turcite on the ways....

I would hurry up and chuck a piece of something straight and long, run an indicator down it mounted to the carriage and make sure that that "bump" didn't knock the headstock/spindle out of alignment with the ways, of course do that after you clean

and am I seeing right that there is paint all over the ways?

on a side note, I do wish that my lathe was more robust like those, hopefully someday I can replace the atlas

I would hurry up and chuck a piece of something straight and long, run an indicator down it mounted to the carriage and make sure that that "bump" didn't knock the headstock/spindle out of alignment with the ways, of course do that after you clean

and am I seeing right that there is paint all over the ways?

on a side note, I do wish that my lathe was more robust like those, hopefully someday I can replace the atlas

Last edited: