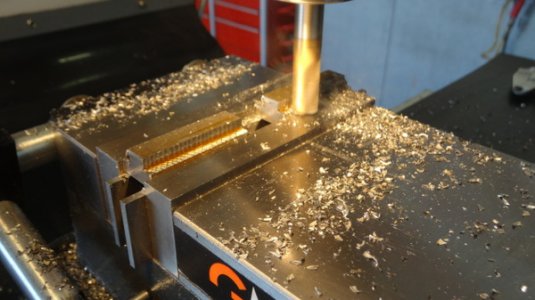

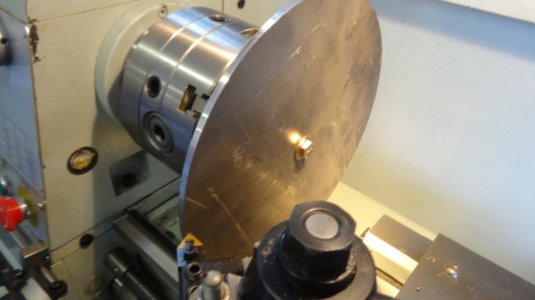

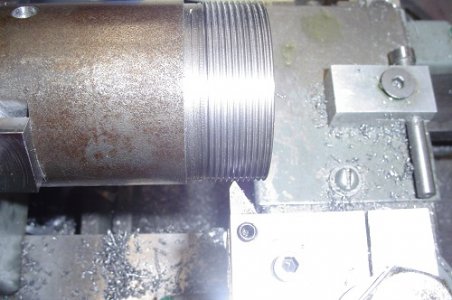

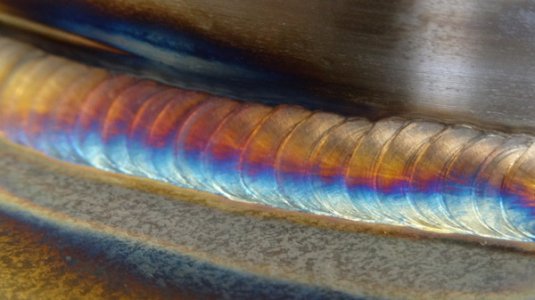

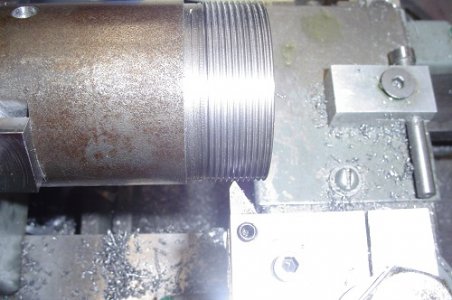

I've been working toward an ER40 collet holder for my Clausing/Atlas MK2 for a couple of weeks. last weekend I found I had to cut internal threads feeding left, if I reversed the spindle and fed right, the lead screw would walk and make inconsistent threads. I drilled through from the other end at 1" diameter for clearance for the threading tool and chased the 1" 10 thread. Without removing the piece from the chuck I removed the chuck and successfully screwed the new holder onto the spindle. It locks up tight with about .0005 runout on the turned OD. I spent most of this week boring out the 8º taper, there seems to be a tiny flare to it, bluing wipes off on a wide band in the middle of the collet. At present I can live with that, maybe sand it out later. Next is to cut the m50 by 1/5 threads. My manual tells me the gears to use to chase 1.5 metric threads, but I had to set it up and check for travel per rev to be sure. Yep, .058 per rev is 1.5 metric pitch. That's good to go. Next is to figure out how to cut the threads without opening the half nut. Instructions said to reverse the motor, so that's what I did. I wondered about reversing the feed, but didn't want to take the chance on losing the thread. I cut the first 3/4 of the thread .002 at a pass, the last .01 at .001 every other pass, spring in between. The last spring pass was enough to let the nut screw all the way on. Here's the set up for chasing the threads, I expect you've all done or at least seen this.

I've lost the use of PhotoShop, sorry about the glare.

I began to wonder, just how concentric my holder was, so nothing would do until put a collet in with a pin and checked run out. The picture doesn't show it well, (sorry, no PhotoShop) but to my trained eye, the needle moves .0002. Yes, that 's good enough. I hope it will repeat, when I remove and replace the holder, but I'm not going to check that now, no point in taunting the Devil.

Still have to finish the OD, and the anti-unscrew clamp, but other than that I'm ready for ER40 work.