- Joined

- Feb 2, 2014

- Messages

- 1,063

Hey roadie33. I thought I had been everywhere in Kansas but I don't think I've even heard of Ozawkie!Nice threading.

If drawers are wood then fine oil finish with tough clear coat and make sure finish is glass smooth and not something that your oils will attack.Black shows dirt pretty well.

Quit wiping down your machines for a week or so, until everything converges to the same shade of gray. Then buy paint that color.

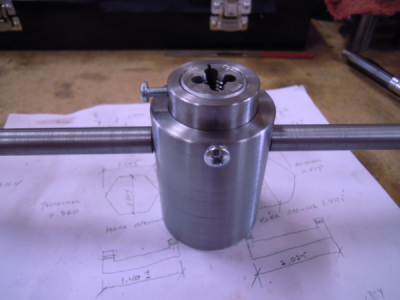

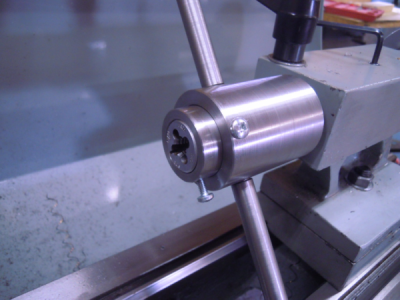

Forgot to post this here but I made a fancy pants chip rake a few days ago.