F

f350ca

Forum Guest

Register Today

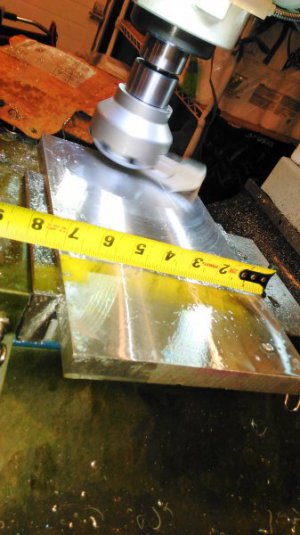

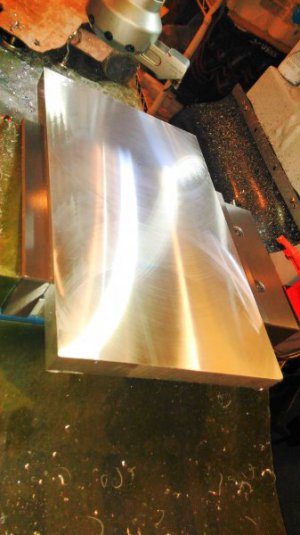

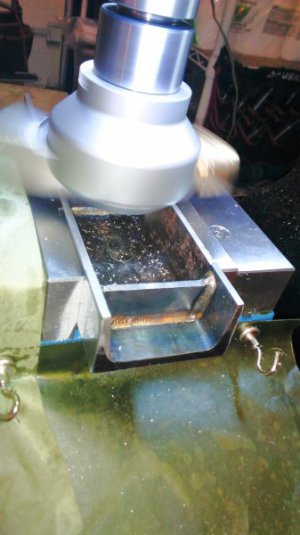

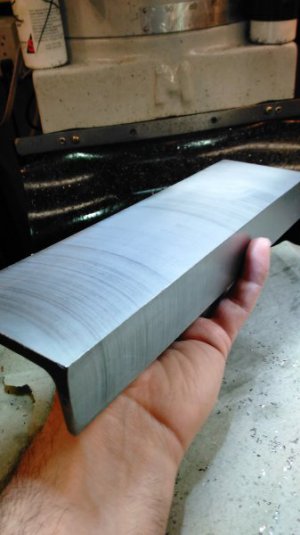

Nice machining on the flywheel weight, does the added mass not need to be balanced though.

Greg

Greg

That's interesting Greg, I never considered that possibility. I have no way to check the balance at the speeds this engine is capable of. I'll be sure to let the owner know there may be a balance problem. I will let you know how it turns out.I've had to balance symmetrically machined components on several occasions. The only explanation I can come up with is that mild steel isn't that homogeneous, which might explain why some areas machine nicer than others. Here is a sanding disk I made, its 16 inches in dia and spins at 1800 rpm. The first time I spun it up the sander danced across the floor. The drilled holes were required to get a static balance.

Greg

Static balance will help, As most steel I have worked with seems to be heavier on one side that the other. Even engine stuff for cars etc all seem to need some kind of balance. Like John did just small drill spots to take a little away then re check itI may try checking the static balance if I have time before he picks it up.