- Joined

- Mar 12, 2014

- Messages

- 1,531

Over the last couple of nights I have been fabricating/machining the components for a Watts link for our coach.

Watts link pivot plate, H-frame clamps, rod ends and some scrap 1"x.095" DOM tubing for the links and some 1" 1095 steel to machine the threaded weld-in bungs.

5/8"-18 rod ends that I procured from McMaster Carr.

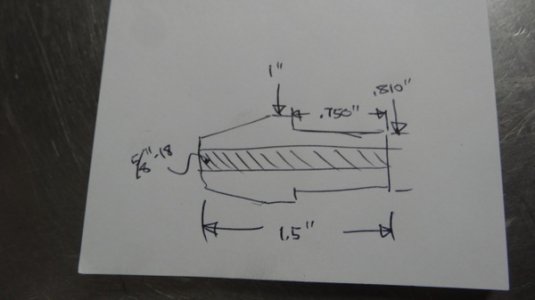

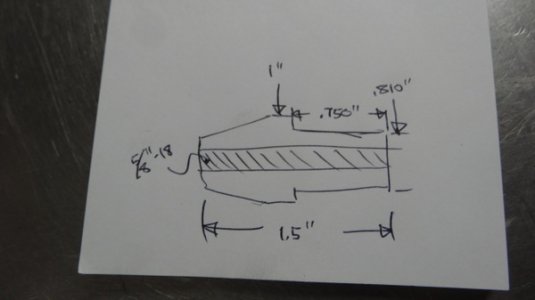

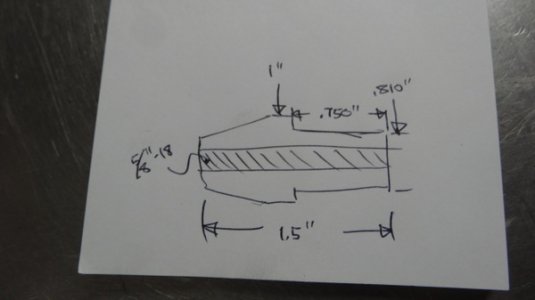

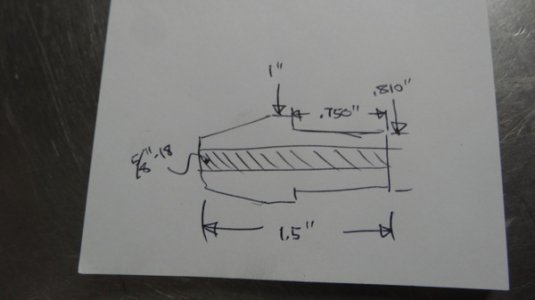

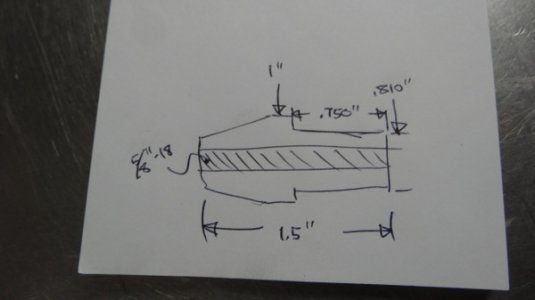

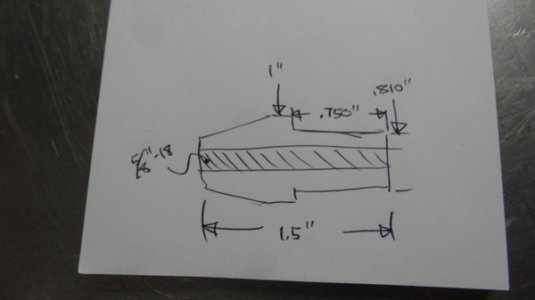

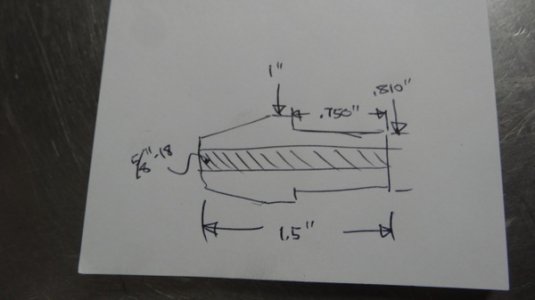

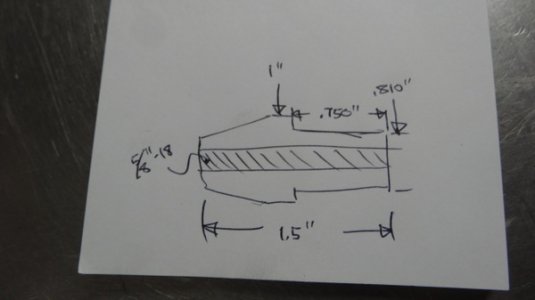

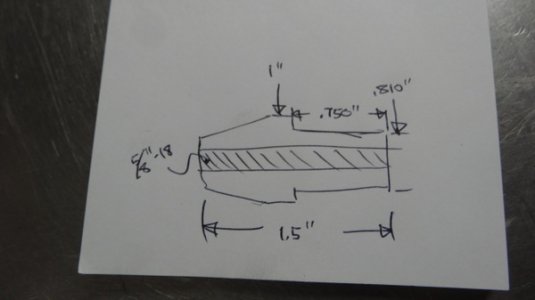

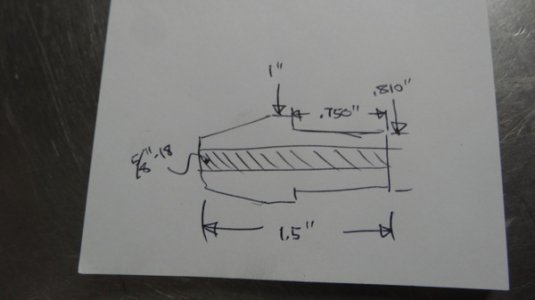

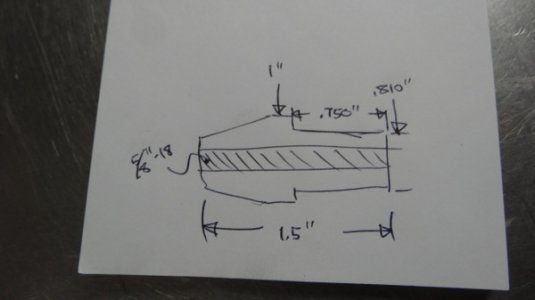

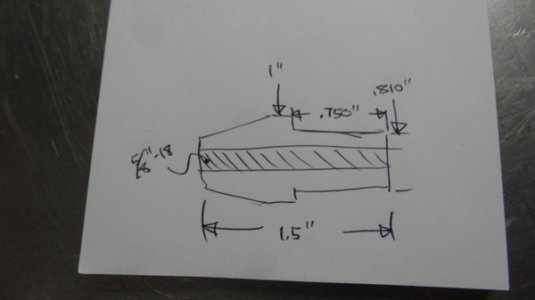

Quick drawing for weld-in threaded bungs.

Machining the threaded bungs.

Making progress.

One completed the others ready for their last machining step, the taper. More for cosmetics than anything at this point. I don't know why, no one will ever see them up under the front suspension of the coach.

All bungs completed and the ready for welding into the 1"x.095" DOM tubing.

Mike.

Watts link pivot plate, H-frame clamps, rod ends and some scrap 1"x.095" DOM tubing for the links and some 1" 1095 steel to machine the threaded weld-in bungs.

5/8"-18 rod ends that I procured from McMaster Carr.

Quick drawing for weld-in threaded bungs.

Machining the threaded bungs.

Making progress.

One completed the others ready for their last machining step, the taper. More for cosmetics than anything at this point. I don't know why, no one will ever see them up under the front suspension of the coach.

All bungs completed and the ready for welding into the 1"x.095" DOM tubing.

Mike.