Thank you for the idea . I need to make a set for barrel crowning . Cut up beer can works but I need three hands to tighten the chuck.If your three jaw chuck has two piece jaws you could machine soft jaws to fit the questionable gear and recut the bore for an oversized bushing.

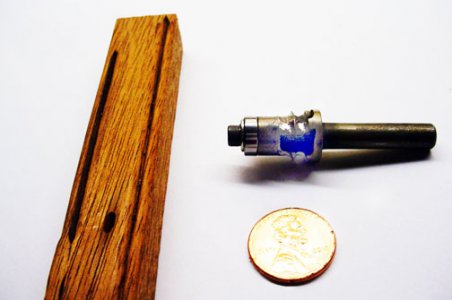

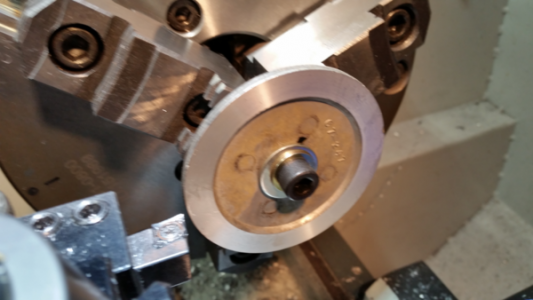

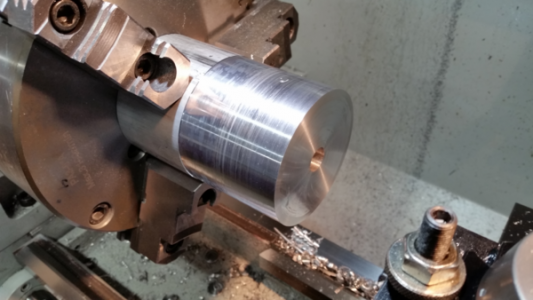

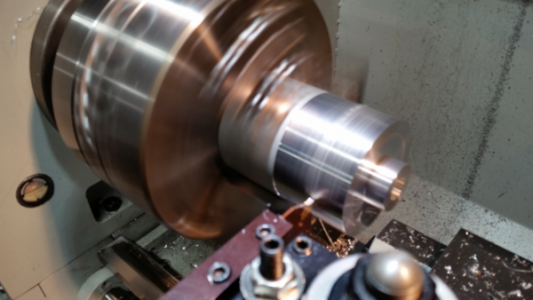

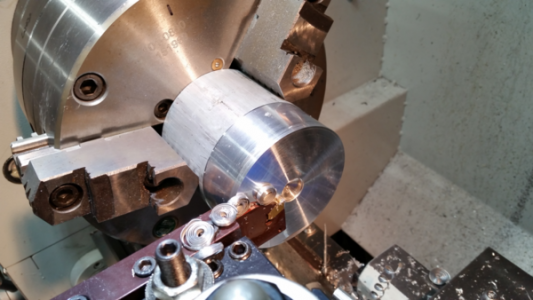

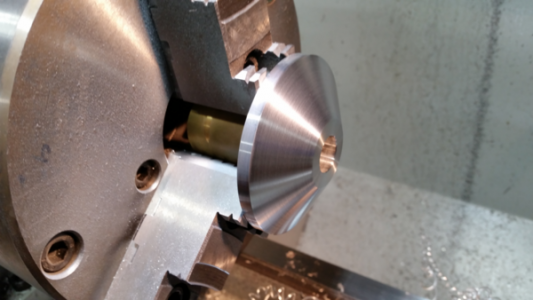

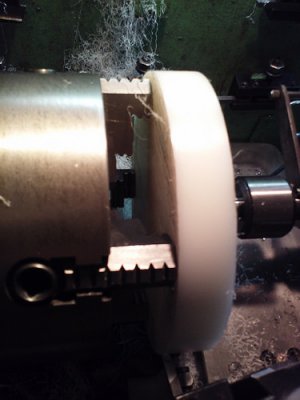

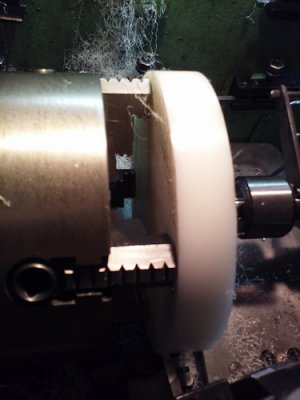

The small gear on this set was damaged, I used soft jaws to hold it while I machined the damaged gear away to press a new one on.

Greg

Sent from my SAMSUNG-SM-G900A using Tapatalk