-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

- Forums

- THE PROJECTS AREA

- PROJECT OF THE DAY --- WHAT DID YOU DO IN YOUR SHOP TODAY?

- Project of the Day Mega-Thread Archives

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

2017 POTD Thread Archive

- Thread starter jpfabricator

- Start date

F

Firestopper

Forum Guest

Register Today

Probably a tool for placing grips (re-gripping) on golf clubs. Many grips require installation a certain way on accordance with the head of the club.

A strap handle would finish up you case nicely Franco.

A strap handle would finish up you case nicely Franco.

- Joined

- Feb 24, 2015

- Messages

- 1,382

Paco is correct. There is an up and down on golf club grips. The gripping station clamps the club shaft and has an alignment device that indexes the head of the club so you can slip the new grip on straight. After removing to old grip, you re-wrap the shaft with double sided tape which is wetted with solvent so the new grip can slide on. It also has a pan to catch and recycle excess grip solvent.

I'm not decided on putting a handle on it. It will spend most of its time stored and probably have things stacked on it. It's pretty heavy so it will not be on the top of the stack.

The grip station is gangly and awkward to carry and store — thus the case.

I'm not decided on putting a handle on it. It will spend most of its time stored and probably have things stacked on it. It's pretty heavy so it will not be on the top of the stack.

The grip station is gangly and awkward to carry and store — thus the case.

- Joined

- Dec 22, 2015

- Messages

- 561

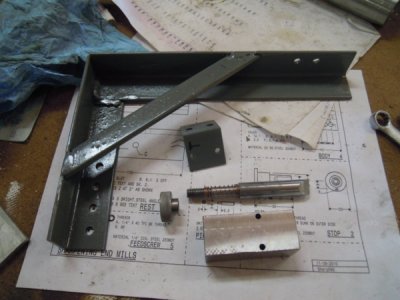

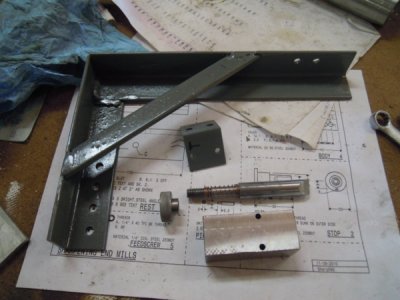

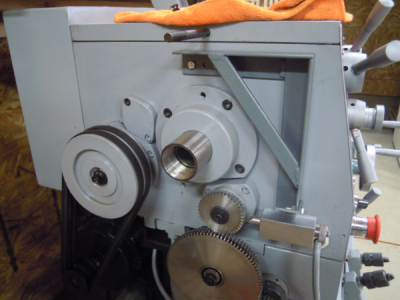

I wanted an indexer on my lathe so I could engrave lines on dials ..... don't know why since I have no need for any dials or other engraving but I wanted one, so here is what I came up with. Some angle iron welded together and drilled so I could use some existing holes in the lathe headstock. I had to add a brace after the initial trial, as there was too much flex in the original setup. The brace fixed that. Here are the pieces.

Looks like I should have done some clean up before painting.

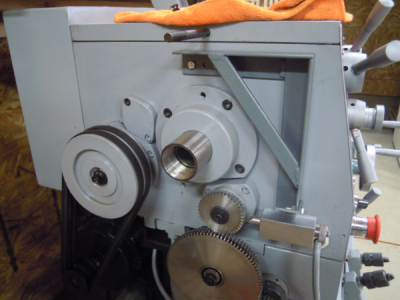

Here it is on the lathe.

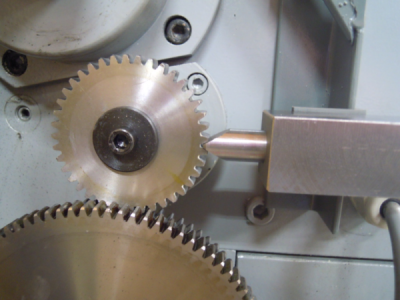

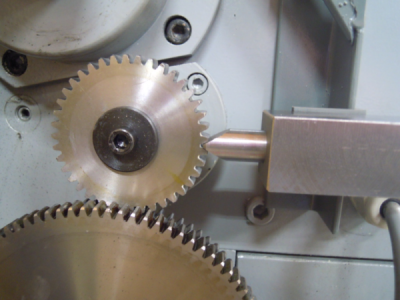

A close up of the indexing pin in the gear. The lathe came with 40, 50 and 60 tooth gears. Which I think will do all I want, unless I find a need for 100 divisions. Then I will have to make something using the RT and dividing plates.

As luck would have it, the whole thing even fits under the cover. Not planned just dumb luck ....... no I take that back it was planned.

And here is the first trial at engraving some lines on a piece of scrap.

One thing that annoyed me: was, after drilling and tapping the holes for the 8 x 32 machine screws I went to install the angle plate and the cap head machine screws fell in to the holes. WHAT... I check to see if I used the wrong drill bit or tap and nope. I get a different 8 x 32 machine screw from a different package and the fit is good. I check the cap head machine screws that came in an assortment package from Princess Auto and all of the 8 x 32 screws are undersized. They are not 6's or 8's. Not sure if I will take them back or not.

Another thing I learned (this time without damaging something) is that it is crucial to make sure the indexing pin is not engaged when the lathe is going to be used for turning. After my trial engraving I was just about to start the lathe to do some turning and a split second before engaging the drive I thought about it. Too close for comfort!

Looks like I should have done some clean up before painting.

Here it is on the lathe.

A close up of the indexing pin in the gear. The lathe came with 40, 50 and 60 tooth gears. Which I think will do all I want, unless I find a need for 100 divisions. Then I will have to make something using the RT and dividing plates.

As luck would have it, the whole thing even fits under the cover. Not planned just dumb luck ....... no I take that back it was planned.

And here is the first trial at engraving some lines on a piece of scrap.

One thing that annoyed me: was, after drilling and tapping the holes for the 8 x 32 machine screws I went to install the angle plate and the cap head machine screws fell in to the holes. WHAT... I check to see if I used the wrong drill bit or tap and nope. I get a different 8 x 32 machine screw from a different package and the fit is good. I check the cap head machine screws that came in an assortment package from Princess Auto and all of the 8 x 32 screws are undersized. They are not 6's or 8's. Not sure if I will take them back or not.

Another thing I learned (this time without damaging something) is that it is crucial to make sure the indexing pin is not engaged when the lathe is going to be used for turning. After my trial engraving I was just about to start the lathe to do some turning and a split second before engaging the drive I thought about it. Too close for comfort!

More than a day's work but finished up a dozen Kant Twist style clamps for giveaways. My inspiration came from another forum member that made some of these a few months back. The drawings came from the internet and most of the materials came from my scrap box. Because I was making twelve of these I wanted to use the CNC mill to do as much as possible. There were a lot of pins to make and doing them on the CNC saved a ton of time. The only parts made in the lathe and manual mill were the screw assemblies.

Tom S.

Tom S.

- Joined

- Jun 26, 2014

- Messages

- 619

Any chance of a link? They look good.The drawings came from the internet

I went to the scrap yard yesterday and found a gib or way from a machine that had been disassembled in a 55 gallon barrel, it is 1 7/8 x 2 1/4 X 36 inches in length, it has 5 spot faces holes for allen bolts to hold it down and flush or slightly below the surface, on one face is a serpentine oil or grease groove for lubrication. Would anyone know what type of Brass or Bronze this material is? THANKS.

F

Firestopper

Forum Guest

Register Today

Another thing I learned (this time without damaging something) is that it is crucial to make sure the indexing pin is not engaged when the lathe is going to be used for turning. After my trial engraving I was just about to start the lathe to do some turning and a split second before engaging the drive I thought about it. Too close for comfort!

I'm very surprised your lathe doesn't have a safety switch that prevents the machine from starting with the cover removed. You might want to add one for a couple of good reasons, one of which you mentioned.

Last edited by a moderator: