I have some parts to sandblast and my poor old Harbor Freight blast cabinet needed a complete overhaul, so today was the day for a rebuild and some enhancements.

View attachment 232838

So off to Home Depot for a few odds & ends. New acrylic to replace the frosted glass window, new LED lighting, and some screws to fasten the window frame from the outside.

I looked at all the 2 ft LED lights they had displayed and this one hurt my eyes to look at it, so in the cart. A little pricy at $65.00 but a lot of light.

http://www.homedepot.com/s/2%20ft.%20led%20light%20mnlk?NCNI-5

I removed the 2 lamp fixture and installed the new one. About 2 inches square so I have room to install another later if I think I need it, but one seems to be fine. Links to another lamp with a link cable.

This was the glass window, would make a good privacy window for a bathroom, no wonder I couldn't see much through it. Kinda had a couple places left that I could sorta see through.

View attachment 232830

View attachment 232830

This is the original suction tube. It is built completely wrong, as I'll show in the next picture.

The blue air line is a modification I made the last time I sandblasted the parts (fishing rod holder brackets) you see in the picture. It kinda worked to help blow the sand up the tube to get more volume.

View attachment 232837

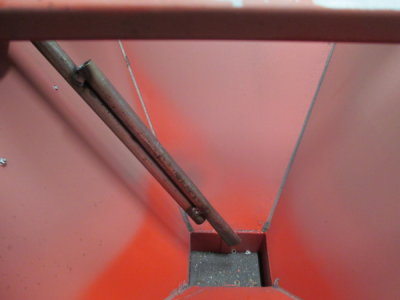

This is the new suction tube, with the ''stiffener'' tube on the top where it is supposed to be. This creates a bit of an air pocket below and controls the sand flow into the suction tube. Makes it much more consistent and clog resistant. Also requires less air to flow the same volume of sand because the sand is not packing around the suction tube.

View attachment 232831

And a top view showing the slightly squished profile of the ''stiffener''

View attachment 232832

And installed

View attachment 232833

A somewhat modified stock gun. Note the short flex hose and the top entry to the gun. Works much better this way and you can still reach anywhere in the cabinet. Eliminates about 2 feet of hose. To get top entry, just unscrew the air nozzle, flip it over, and screw the air nozzle back in. I have a solenoid valve and a foot switch to run the air, thus the zip-tied trigger.

View attachment 232834

The genius that designed the cabinet wasn't thinking about how to replace the glass.

They use screws through the frame with nuts & washers on the back side. Just about impossible to reach the far end unless you have 2 people or 6 foot arms. So I used some #14 x 1 sheet metal screws to fit the existing holes in the sheet metal, drilled out the frame holes to 1/4 inch, and screwed it in from the outside. Now I can change the window in about 5 minutes and not struggle to do it.

View attachment 232835

View attachment 232835

And the view through the new window after testing the blaster. With the mods to the suction tube and a new nozzle I get about twice the sand and am using about half the air I was before. I'll see how the acrylic holds up, I bought enough to make 3 windows. If it frosts up too quickly, I have a whole roll of 3 mil Mylar. I'll try to make a quick change sacrificial shield.

View attachment 232836

Overall, I'm going to call this a success for now

, but we'll see how it really works out by the time I'm done with 216 parts.

, but we'll see how it really works out by the time I'm done with 216 parts.

, but we'll see how it really works out by the time I'm done with 216 parts.