- Joined

- Dec 11, 2014

- Messages

- 891

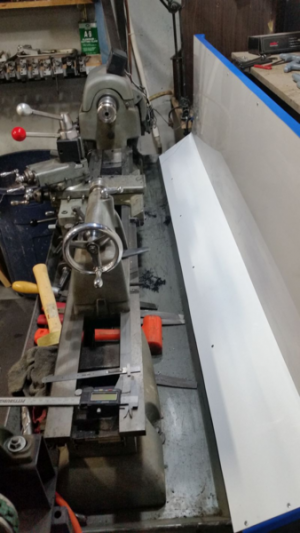

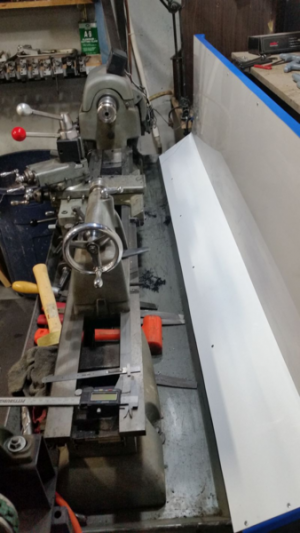

Finished up a guard for the Lathe to keep the chips from being slung all over behind the lathe onto the floor.

It's height is adjustable and I made it movable so if I need to use the Taper Attachment I can just roll it out of the way.

Used 1" and 1-1/4" tubing for the upper frame and attached some .090 aluminum sheet scraps I picked up at an Auction. The place I got them from built those small enclosed trailers that are 6' x 8'. One side is plain aluminum and the other is painted white. I picked up five 4' x 8' sheets, two 4' x 10' and a lot of misc sized pieces, it was all sandwiched between some sheets of plywood and you couldn't even see the aluminum sheets. I was just bidding on the plywood. When I went to load the next day, is when I found the aluminum and I was totally surprised. All of it for $15.

It's height is adjustable and I made it movable so if I need to use the Taper Attachment I can just roll it out of the way.

Used 1" and 1-1/4" tubing for the upper frame and attached some .090 aluminum sheet scraps I picked up at an Auction. The place I got them from built those small enclosed trailers that are 6' x 8'. One side is plain aluminum and the other is painted white. I picked up five 4' x 8' sheets, two 4' x 10' and a lot of misc sized pieces, it was all sandwiched between some sheets of plywood and you couldn't even see the aluminum sheets. I was just bidding on the plywood. When I went to load the next day, is when I found the aluminum and I was totally surprised. All of it for $15.