Re: The next project

Well said. The quality of his work makes me 'furious'.

I am observing the progress of this project and:

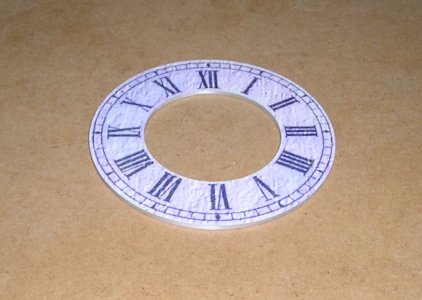

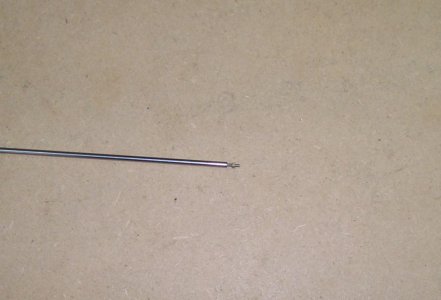

1. It makes me proud that there are people (eg. hare) who appreciate decent piece of clock work.

2. And it makes me furious that, unfortunately, the majority of hm... us people out there prefer to go to one of the junk-garbage shops with products made by robots in one of the largest of countries, be happy to buy piece of crude plastic with a battery and throw it away within few months.

Very pleasing project.

J

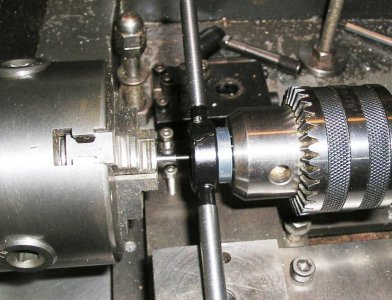

but your craftsmanship is awesome.

David

Well said. The quality of his work makes me 'furious'.

I am observing the progress of this project and:

1. It makes me proud that there are people (eg. hare) who appreciate decent piece of clock work.

2. And it makes me furious that, unfortunately, the majority of hm... us people out there prefer to go to one of the junk-garbage shops with products made by robots in one of the largest of countries, be happy to buy piece of crude plastic with a battery and throw it away within few months.

Very pleasing project.

J