-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

B

Bill Gruby

Forum Guest

Register Today

Nope, not me but you might want to discuss it with my dogs.

"Bill"

"Bill"

Ok...... I have the information for the balance weights. I will make a basic drawing and post it. They are complex little things for what they are, but won't be difficult to make. I will put the groove dimensions on the print for the weights. the prints get cluttered with all the dimensions. ..... Oh.... this may take a day or two.

- Joined

- Jan 21, 2013

- Messages

- 880

There's an old thread by Ray C (miss that guy) that discusses this. Might help?Both Bills are correct. I used the standard thread so you can buy the tool or as I will do ..... Make it.

The balance groove dimensions are missing because I am trying to get a price on the weight set as I can't figure a way to make them.....yet. If they are inexpensive . I will buy them. If not ....I really don't have a back up plan . I have found a couple designs of weights , I'm still working on how to make them . I will make a sketch of the weight and maybe someone on here will have an idea.

http://www.hobby-machinist.com/threads/balanced-grinder-hubs.16950/

There's an old thread by Ray C (miss that guy) that discusses this. Might help?

http://www.hobby-machinist.com/threads/balanced-grinder-hubs.16950/

Thanks for the link. There was a lot of good info there. There also seems to be an ongoing feud on several forums and discussion on this one ( in some old threads), that the balancing is totally unnecessary on wheels 7" and under. ( we are using an 8" wheel I think). But, it seems there are differing opinions from even the grinder manufacturers on this. That being said, I think it will be a matter of preference whether to include the balance feature on this grinder and is a simple matter of you make the groove and weights .... or you don't. I however .. lean towards balancing is a good option and intend to make the balance system.

A

Andre

Forum Guest

Register Today

Balance the wheel!!!!! Finishes improve dramatically.....

B

Bill Gruby

Forum Guest

Register Today

Dressing the wheel is faster also.

"Bill"

"Bill"

- Joined

- Jan 21, 2013

- Messages

- 880

Good point, which raises a question for me since I know nothing about this; If you balance the wheel before using it, and then dress it, It becomes concentric with the spindle, but now what happens to the balance? If you're removing a significant amount of material to produce a beveled edge as I've seen demonstrated, it seems like this could cause an issue. I always assumed balancing made sense before now...Dressing the wheel is faster also.

"Bill"

Ideally you balance the wheel , then true the OD, then balance it again. This is more time consuming but gives optimum results.Good point, which raises a question for me since I know nothing about this; If you balance the wheel before using it, and then dress it, It becomes concentric with the spindle, but now what happens to the balance? If you're removing a significant amount of material to produce a beveled edge as I've seen demonstrated, it seems like this could cause an issue. I always assumed balancing made sense before now...

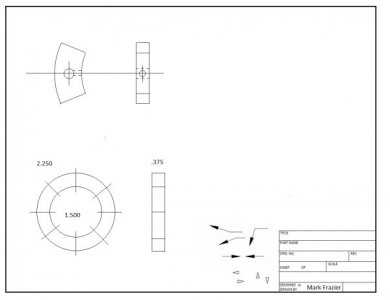

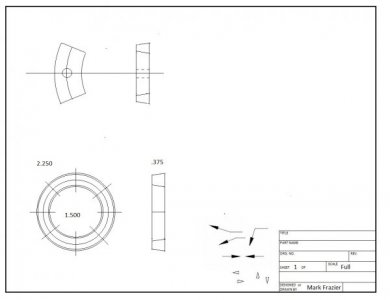

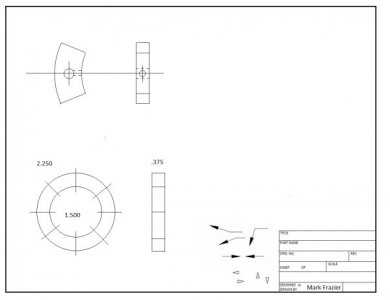

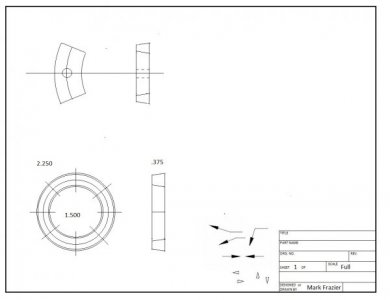

Here are two drafts for balancing weights. THESE ARE ONLY DRAFTS to demonstrate the methods

This is the most popular design I have found, but also the most difficult to make in my opinion. ( I see why they get $800 - $1000 for an arbor now

This is the most popular design I have found, but also the most difficult to make in my opinion. ( I see why they get $800 - $1000 for an arbor now  ). I saw a guy make some of these on the web ( wish I would have saved the post). You make a ring that just slips into the arbor groove. the tapped hole gets a grub screw that pushes a ball bearing against the side of the groove to secure the weight. There would be a slight dish in the one side of the groove for the ball bearing to lock into. To me this one is a complicated little doo dad. I like the next one better.

). I saw a guy make some of these on the web ( wish I would have saved the post). You make a ring that just slips into the arbor groove. the tapped hole gets a grub screw that pushes a ball bearing against the side of the groove to secure the weight. There would be a slight dish in the one side of the groove for the ball bearing to lock into. To me this one is a complicated little doo dad. I like the next one better.

This system seems easier to me. There are two rings that hand press into one another, the outer and inner edges are tapered to match the taper in the arbor groove. The ring is divided into 6 or 8 parts and a hole is drilled and tapped in each segment BEFORE the segments are cut apart. The two halves are put in the arbor groove and then a grub screw tightens it in place by lifting the weight slightly when screwed in. As I said, I think this would be easier to machine and make.

This system seems easier to me. There are two rings that hand press into one another, the outer and inner edges are tapered to match the taper in the arbor groove. The ring is divided into 6 or 8 parts and a hole is drilled and tapped in each segment BEFORE the segments are cut apart. The two halves are put in the arbor groove and then a grub screw tightens it in place by lifting the weight slightly when screwed in. As I said, I think this would be easier to machine and make.

THESE ARE ONLY DRAFTS

Opinions and comments appreciated.

This is the most popular design I have found, but also the most difficult to make in my opinion. ( I see why they get $800 - $1000 for an arbor now

This is the most popular design I have found, but also the most difficult to make in my opinion. ( I see why they get $800 - $1000 for an arbor now  ). I saw a guy make some of these on the web ( wish I would have saved the post). You make a ring that just slips into the arbor groove. the tapped hole gets a grub screw that pushes a ball bearing against the side of the groove to secure the weight. There would be a slight dish in the one side of the groove for the ball bearing to lock into. To me this one is a complicated little doo dad. I like the next one better.

). I saw a guy make some of these on the web ( wish I would have saved the post). You make a ring that just slips into the arbor groove. the tapped hole gets a grub screw that pushes a ball bearing against the side of the groove to secure the weight. There would be a slight dish in the one side of the groove for the ball bearing to lock into. To me this one is a complicated little doo dad. I like the next one better. This system seems easier to me. There are two rings that hand press into one another, the outer and inner edges are tapered to match the taper in the arbor groove. The ring is divided into 6 or 8 parts and a hole is drilled and tapped in each segment BEFORE the segments are cut apart. The two halves are put in the arbor groove and then a grub screw tightens it in place by lifting the weight slightly when screwed in. As I said, I think this would be easier to machine and make.

This system seems easier to me. There are two rings that hand press into one another, the outer and inner edges are tapered to match the taper in the arbor groove. The ring is divided into 6 or 8 parts and a hole is drilled and tapped in each segment BEFORE the segments are cut apart. The two halves are put in the arbor groove and then a grub screw tightens it in place by lifting the weight slightly when screwed in. As I said, I think this would be easier to machine and make.THESE ARE ONLY DRAFTS

Opinions and comments appreciated.