I got it off eBay. They have this one for 120 volts and u saw a bigger one for 220 volts. There are several sellers on eBay.Mark would you post a link for that switch, never seen one of those before.

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Another Tool & Cutter Grinder

- Thread starter Mark_f

- Start date

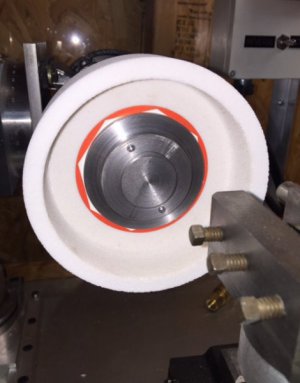

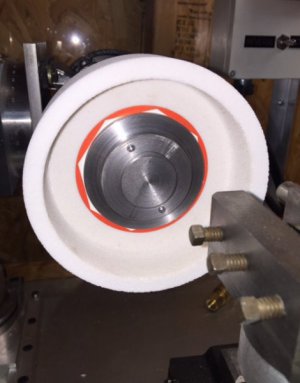

I made the arbor, mounted a wheel and finished the electricals today.

I machined a 1 1/4" arbor with a 1/2" stub on the rear to fit the ER 20 collet. I machined two washers for the wheel. They have a .375" wide surface around the outer edge to contact the wheel. the middle is relieved .050" deep. They are 2.5" diameter. I got them machined within .003" parallel on the two faces. I check the run out on the ER 20 collet and it is .002 T.I.R. I thought that was pretty good. I mounted the wheel on the arbor ( which I made using my new ER 40 collet system and there is about .0005" T.I.R.) and fired it up for the first time. IT SHOOK LIKE CRAZY! I set up a diamond in the vise and trued up the periphery of the wheel and the face of the wheel. It calmed down and runs smooth and quiet now.

I machined a 1 1/4" arbor with a 1/2" stub on the rear to fit the ER 20 collet. I machined two washers for the wheel. They have a .375" wide surface around the outer edge to contact the wheel. the middle is relieved .050" deep. They are 2.5" diameter. I got them machined within .003" parallel on the two faces. I check the run out on the ER 20 collet and it is .002 T.I.R. I thought that was pretty good. I mounted the wheel on the arbor ( which I made using my new ER 40 collet system and there is about .0005" T.I.R.) and fired it up for the first time. IT SHOOK LIKE CRAZY! I set up a diamond in the vise and trued up the periphery of the wheel and the face of the wheel. It calmed down and runs smooth and quiet now.

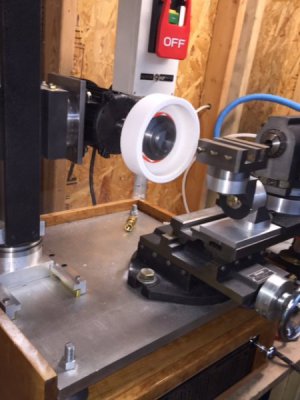

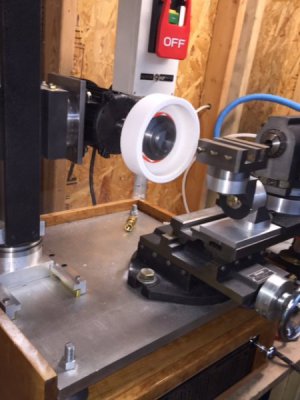

This thing runs great. I am going to try and grind a lathe tool with it tomorrow to see how it works. Seems to have plenty of power. I have to make a wheel guard and hook up the air system for the air spindle. I think this grinder is going to work great and it is sooooo much easier to build than the Bonelle was. A little more work to do, but it is getting close to done. I have found it weighs a little over 200 pounds so it sets steady and does not move. I put an indicator against the wheel and tried to flex the column and I could only flex a couple thousandths if I pressed really hard at the top of the column. It is nice and stable.

This thing runs great. I am going to try and grind a lathe tool with it tomorrow to see how it works. Seems to have plenty of power. I have to make a wheel guard and hook up the air system for the air spindle. I think this grinder is going to work great and it is sooooo much easier to build than the Bonelle was. A little more work to do, but it is getting close to done. I have found it weighs a little over 200 pounds so it sets steady and does not move. I put an indicator against the wheel and tried to flex the column and I could only flex a couple thousandths if I pressed really hard at the top of the column. It is nice and stable.

I also plan to install a work light. I am looking for a good deal on one of those articulated lights with a magnifying glass in the center. I have four different wheels do I have to make some more arbors also. And I want to make the radius tool for grinding ball end mills.

So..... Keep watching this space.

I machined a 1 1/4" arbor with a 1/2" stub on the rear to fit the ER 20 collet. I machined two washers for the wheel. They have a .375" wide surface around the outer edge to contact the wheel. the middle is relieved .050" deep. They are 2.5" diameter. I got them machined within .003" parallel on the two faces. I check the run out on the ER 20 collet and it is .002 T.I.R. I thought that was pretty good. I mounted the wheel on the arbor ( which I made using my new ER 40 collet system and there is about .0005" T.I.R.) and fired it up for the first time. IT SHOOK LIKE CRAZY! I set up a diamond in the vise and trued up the periphery of the wheel and the face of the wheel. It calmed down and runs smooth and quiet now.

I machined a 1 1/4" arbor with a 1/2" stub on the rear to fit the ER 20 collet. I machined two washers for the wheel. They have a .375" wide surface around the outer edge to contact the wheel. the middle is relieved .050" deep. They are 2.5" diameter. I got them machined within .003" parallel on the two faces. I check the run out on the ER 20 collet and it is .002 T.I.R. I thought that was pretty good. I mounted the wheel on the arbor ( which I made using my new ER 40 collet system and there is about .0005" T.I.R.) and fired it up for the first time. IT SHOOK LIKE CRAZY! I set up a diamond in the vise and trued up the periphery of the wheel and the face of the wheel. It calmed down and runs smooth and quiet now.  This thing runs great. I am going to try and grind a lathe tool with it tomorrow to see how it works. Seems to have plenty of power. I have to make a wheel guard and hook up the air system for the air spindle. I think this grinder is going to work great and it is sooooo much easier to build than the Bonelle was. A little more work to do, but it is getting close to done. I have found it weighs a little over 200 pounds so it sets steady and does not move. I put an indicator against the wheel and tried to flex the column and I could only flex a couple thousandths if I pressed really hard at the top of the column. It is nice and stable.

This thing runs great. I am going to try and grind a lathe tool with it tomorrow to see how it works. Seems to have plenty of power. I have to make a wheel guard and hook up the air system for the air spindle. I think this grinder is going to work great and it is sooooo much easier to build than the Bonelle was. A little more work to do, but it is getting close to done. I have found it weighs a little over 200 pounds so it sets steady and does not move. I put an indicator against the wheel and tried to flex the column and I could only flex a couple thousandths if I pressed really hard at the top of the column. It is nice and stable.I also plan to install a work light. I am looking for a good deal on one of those articulated lights with a magnifying glass in the center. I have four different wheels do I have to make some more arbors also. And I want to make the radius tool for grinding ball end mills.

So..... Keep watching this space.

- Joined

- Oct 20, 2014

- Messages

- 495

That is fantastic. Looks a lot less 'spindly' than the quorn or bonelle, and much less complex to boot.. As for the weight... While I love my little Atlas horizontal mill, it would fit comfortably on the table of my big Cincinatti mill. But, neither of them get moved. That tool grinder is going to be a well-used fixture in the shop, and the weight and over-engineering will make sure it's a tool you don't have to fuss with or fiddle with. You just use it, and know it'll do a good job. Same with the Atlas.

Excellent work as usual, but I have to ask, do you plan to write a 'How to use this grinder' document? Lathe bits would be simple to grind, but sharpening the flutes of an endmill seems like black magic to (hopefully not just me) the rest of us that have never touched a tool grinder. But I do have a few buggered up endmills that need some grinding wheel love, as I'm sure most of us do. I'd enjoy learning the hows and whys of grinding them.

I'd enjoy learning the hows and whys of grinding them.

Excellent work as usual, but I have to ask, do you plan to write a 'How to use this grinder' document? Lathe bits would be simple to grind, but sharpening the flutes of an endmill seems like black magic to (hopefully not just me) the rest of us that have never touched a tool grinder. But I do have a few buggered up endmills that need some grinding wheel love, as I'm sure most of us do.

That is fantastic. Looks a lot less 'spindly' than the quorn or bonelle, and much less complex to boot.. As for the weight... While I love my little Atlas horizontal mill, it would fit comfortably on the table of my big Cincinatti mill. But, neither of them get moved. That tool grinder is going to be a well-used fixture in the shop, and the weight and over-engineering will make sure it's a tool you don't have to fuss with or fiddle with. You just use it, and know it'll do a good job. Same with the Atlas.

Excellent work as usual, but I have to ask, do you plan to write a 'How to use this grinder' document? Lathe bits would be simple to grind, but sharpening the flutes of an endmill seems like black magic to (hopefully not just me) the rest of us that have never touched a tool grinder. But I do have a few buggered up endmills that need some grinding wheel love, as I'm sure most of us do.I'd enjoy learning the hows and whys of grinding them.

Actually, I am in the midst of writing a short article on grinding end mills. Most of that chapter is pretty well finished. I plan on a instruction manual for this grinder.

This is a take off of a popular grinder being sold for $10,000. Mine is not quite as fancy, but is much heavier and I believe will do the same job. I did a lot of scrounging and got some donated materials and I finished this machine at around $300. I think it can be built for around $500 with careful shopping for material and parts.

I will try sharpening an end mill as soon as I get the air supply installed.

The Tool & Cutter grinder is basically done. I will be adding fixtures and will post them as they are made. I decided to grind a couple of tools and see how it works. I must say , I am impressed with the sturdiness and stability. Everything is working as it should.

I removed the air bearing to make room to use the vise. The first tool I ground was a lathe tool. It is simple and will check the grinder operation.

I removed the air bearing to make room to use the vise. The first tool I ground was a lathe tool. It is simple and will check the grinder operation.

The lathe tool Was ground by putting the blank in the vise and just setting the desired angle and grinding. It grinds really nice at .005" per cut. It is much faster and nicer than anything I could do by hand. I am very pleased so far.

The lathe tool Was ground by putting the blank in the vise and just setting the desired angle and grinding. It grinds really nice at .005" per cut. It is much faster and nicer than anything I could do by hand. I am very pleased so far.

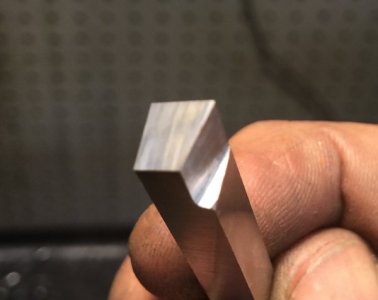

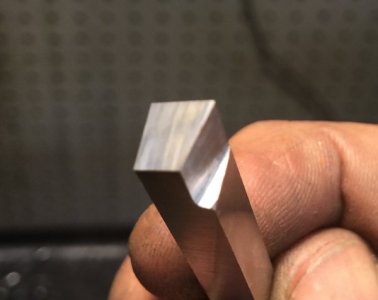

The next tool to grind is an acme threading tool for internal threads. I was going to buy an acme boring bar until I found out they cost over $100 EACH. I took a piece of drill rod and turned an offset on the end in the lathe. Then put it in the grinder vise and ground one angle at a time.

I took a piece of drill rod and turned an offset on the end in the lathe. Then put it in the grinder vise and ground one angle at a time.

I ground the top side flat and then the 29 degree included angle on the end.

I ground the top side flat and then the 29 degree included angle on the end.

All the clearance angles were ground next.

All the clearance angles were ground next.

The finished tool was heat treated to harden. A file won't scratch it , so hopefully it will cut bronze OK. I polished the black off to make it look better. This was basically a test grind , but I will use this tool. From now on, I think I will harden the tool and then grind it to finish. I am pleased anyway.

The finished tool was heat treated to harden. A file won't scratch it , so hopefully it will cut bronze OK. I polished the black off to make it look better. This was basically a test grind , but I will use this tool. From now on, I think I will harden the tool and then grind it to finish. I am pleased anyway.

This is the grinder set up. The hand wheels were a little stiff at first but after a good bit of cranking they are MUCH better. As everything wears in and the gibs get readjusted, I think the machine will work very easily and smooth.

This is the grinder set up. The hand wheels were a little stiff at first but after a good bit of cranking they are MUCH better. As everything wears in and the gibs get readjusted, I think the machine will work very easily and smooth.

(oops.. I must have forgot to edit this photo . It loaded sideways.) I put a cloth over the grinding area to catch the grit as it goes everywhere and i don't want it on the table ways. Cleanup is easier also.

(oops.. I must have forgot to edit this photo . It loaded sideways.) I put a cloth over the grinding area to catch the grit as it goes everywhere and i don't want it on the table ways. Cleanup is easier also.

I figure at the cost of micro boring bars, This grinder will pay for itself after making just a few bars. The machine works excellent and I will be adding the air supply for the air bearing and making a wheel guard. I still have to make a radius fixture for ball end mills. and get a 5C spin fixture for grinding pins or anything round.

This is a learning process, but I can see that it will give great improvement to my tooling capabilities.

I removed the air bearing to make room to use the vise. The first tool I ground was a lathe tool. It is simple and will check the grinder operation.

I removed the air bearing to make room to use the vise. The first tool I ground was a lathe tool. It is simple and will check the grinder operation. The lathe tool Was ground by putting the blank in the vise and just setting the desired angle and grinding. It grinds really nice at .005" per cut. It is much faster and nicer than anything I could do by hand. I am very pleased so far.

The lathe tool Was ground by putting the blank in the vise and just setting the desired angle and grinding. It grinds really nice at .005" per cut. It is much faster and nicer than anything I could do by hand. I am very pleased so far.The next tool to grind is an acme threading tool for internal threads. I was going to buy an acme boring bar until I found out they cost over $100 EACH.

I took a piece of drill rod and turned an offset on the end in the lathe. Then put it in the grinder vise and ground one angle at a time.

I took a piece of drill rod and turned an offset on the end in the lathe. Then put it in the grinder vise and ground one angle at a time. I ground the top side flat and then the 29 degree included angle on the end.

I ground the top side flat and then the 29 degree included angle on the end. All the clearance angles were ground next.

All the clearance angles were ground next. The finished tool was heat treated to harden. A file won't scratch it , so hopefully it will cut bronze OK. I polished the black off to make it look better. This was basically a test grind , but I will use this tool. From now on, I think I will harden the tool and then grind it to finish. I am pleased anyway.

The finished tool was heat treated to harden. A file won't scratch it , so hopefully it will cut bronze OK. I polished the black off to make it look better. This was basically a test grind , but I will use this tool. From now on, I think I will harden the tool and then grind it to finish. I am pleased anyway. This is the grinder set up. The hand wheels were a little stiff at first but after a good bit of cranking they are MUCH better. As everything wears in and the gibs get readjusted, I think the machine will work very easily and smooth.

This is the grinder set up. The hand wheels were a little stiff at first but after a good bit of cranking they are MUCH better. As everything wears in and the gibs get readjusted, I think the machine will work very easily and smooth. (oops.. I must have forgot to edit this photo . It loaded sideways.) I put a cloth over the grinding area to catch the grit as it goes everywhere and i don't want it on the table ways. Cleanup is easier also.

(oops.. I must have forgot to edit this photo . It loaded sideways.) I put a cloth over the grinding area to catch the grit as it goes everywhere and i don't want it on the table ways. Cleanup is easier also.I figure at the cost of micro boring bars, This grinder will pay for itself after making just a few bars. The machine works excellent and I will be adding the air supply for the air bearing and making a wheel guard. I still have to make a radius fixture for ball end mills. and get a 5C spin fixture for grinding pins or anything round.

This is a learning process, but I can see that it will give great improvement to my tooling capabilities.

Last edited by a moderator:

- Joined

- Jun 29, 2014

- Messages

- 4,170

That is correct Bill. That is why I made the point. Some of the hobbyists say " I could never do that good of work". That is self defeating because they can.... They just may not know it. Some folks, even other machinist are in awe of some things I have built , but I see a flawed piece of failure in my view and that is me chasing something unattainable ..... Perfection. Every piece gets better though.

I read something akin to the following..."the greater the circle of light, the greater the circumference of darkness."

What a wonderful build...I suppose you could chase that elusive tenth, but to what end? It's still wonderful!

Sent from my iPhone using Tapatalk