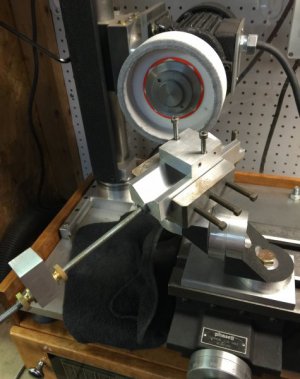

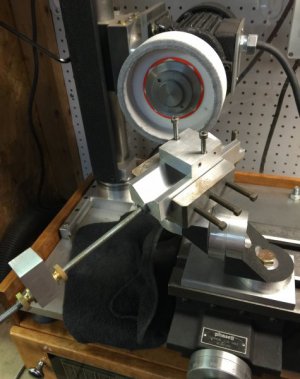

While my precision drill sharpener is great up to 1/2", I needed to sharpen my 1" drill today. I had been hand grinding it and I did a good job but I thought it would be nice to be able to sharpen my big drills to precision like the smaller drills.. So........ I whipped up an attachment for my new T&C grinder to do just that.

I used a block of aluminum, cut a 90 degree "V" in it. Put a 10-24 bolt on each side through a block to clamp the bit in the "V".

The front is relieved to clear the grinding wheel. A stud is adjustable to locate the drill flute in a horizontal position. ( the stud will get a point turned on it now that I know it works.)

The front is relieved to clear the grinding wheel. A stud is adjustable to locate the drill flute in a horizontal position. ( the stud will get a point turned on it now that I know it works.)

A threaded rod with an adjustable block holds the drill in place when indexing.

A threaded rod with an adjustable block holds the drill in place when indexing.

The unit clamps in the swivel vise on the grinder which is set at the required angles.

The unit clamps in the swivel vise on the grinder which is set at the required angles.

Here the drill is mounted and passed in front of the wheel. This side is ground as needed, noting the hand wheel reading. The drill is loosened and turned 180 degrees to grind the other flute. The block at the rear keeps the drill located exactly the same in the fixture. The second flute is ground to the same reading on the hand wheel. Now the secondary angle is ground and the vise is readjusted to the primary angle. The grinding process is repeated to grind the primary angle to achieve a land at the desired width. This whole process took about 10 minutes, but now my large bit is ground precision just like all my other drills.

Here the drill is mounted and passed in front of the wheel. This side is ground as needed, noting the hand wheel reading. The drill is loosened and turned 180 degrees to grind the other flute. The block at the rear keeps the drill located exactly the same in the fixture. The second flute is ground to the same reading on the hand wheel. Now the secondary angle is ground and the vise is readjusted to the primary angle. The grinding process is repeated to grind the primary angle to achieve a land at the desired width. This whole process took about 10 minutes, but now my large bit is ground precision just like all my other drills.

This is the finished drill. Came out perfect!

This is the finished drill. Came out perfect!

It is a little more work and more steps to sharpen drills on the T&C grinder but that is fine as the big drills aren't sharpened that often.

Now that I know this thing works, I will refine it into a nice professional piece of tooling.

I used a block of aluminum, cut a 90 degree "V" in it. Put a 10-24 bolt on each side through a block to clamp the bit in the "V".

The front is relieved to clear the grinding wheel. A stud is adjustable to locate the drill flute in a horizontal position. ( the stud will get a point turned on it now that I know it works.)

The front is relieved to clear the grinding wheel. A stud is adjustable to locate the drill flute in a horizontal position. ( the stud will get a point turned on it now that I know it works.)  A threaded rod with an adjustable block holds the drill in place when indexing.

A threaded rod with an adjustable block holds the drill in place when indexing. The unit clamps in the swivel vise on the grinder which is set at the required angles.

The unit clamps in the swivel vise on the grinder which is set at the required angles. Here the drill is mounted and passed in front of the wheel. This side is ground as needed, noting the hand wheel reading. The drill is loosened and turned 180 degrees to grind the other flute. The block at the rear keeps the drill located exactly the same in the fixture. The second flute is ground to the same reading on the hand wheel. Now the secondary angle is ground and the vise is readjusted to the primary angle. The grinding process is repeated to grind the primary angle to achieve a land at the desired width. This whole process took about 10 minutes, but now my large bit is ground precision just like all my other drills.

Here the drill is mounted and passed in front of the wheel. This side is ground as needed, noting the hand wheel reading. The drill is loosened and turned 180 degrees to grind the other flute. The block at the rear keeps the drill located exactly the same in the fixture. The second flute is ground to the same reading on the hand wheel. Now the secondary angle is ground and the vise is readjusted to the primary angle. The grinding process is repeated to grind the primary angle to achieve a land at the desired width. This whole process took about 10 minutes, but now my large bit is ground precision just like all my other drills.

This is the finished drill. Came out perfect!

This is the finished drill. Came out perfect!It is a little more work and more steps to sharpen drills on the T&C grinder but that is fine as the big drills aren't sharpened that often.

Now that I know this thing works, I will refine it into a nice professional piece of tooling.