Hi all,

I very recently picked up an old 4804 and have begun the process of getting it back into running condition. First order of business seems to be to replace the spindle bearings, as they are without a doubt roached. After that, it's mostly a lot of cleanup, oiling, and other setup to get it dialed in.

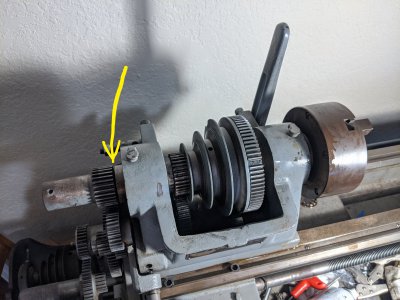

I noticed the spindle locking issue when trying to remove the chuck. I tried the method of engaging the back gears with the lock pin engaged. However, I believe the key for the large spindle gear must have sheared, as the spindle and chuck rotate (albeit with resistance) when the large spindle gear and belt pulleys are locked by the back gears.

Given that the pulley assembly and spindle are no longer fixed to one another, I'm having trouble thinking of a good way to lock the spindle to remove the chuck without high potential for damaging something. Any ideas?

I very recently picked up an old 4804 and have begun the process of getting it back into running condition. First order of business seems to be to replace the spindle bearings, as they are without a doubt roached. After that, it's mostly a lot of cleanup, oiling, and other setup to get it dialed in.

I noticed the spindle locking issue when trying to remove the chuck. I tried the method of engaging the back gears with the lock pin engaged. However, I believe the key for the large spindle gear must have sheared, as the spindle and chuck rotate (albeit with resistance) when the large spindle gear and belt pulleys are locked by the back gears.

Given that the pulley assembly and spindle are no longer fixed to one another, I'm having trouble thinking of a good way to lock the spindle to remove the chuck without high potential for damaging something. Any ideas?