- Joined

- Sep 28, 2014

- Messages

- 11

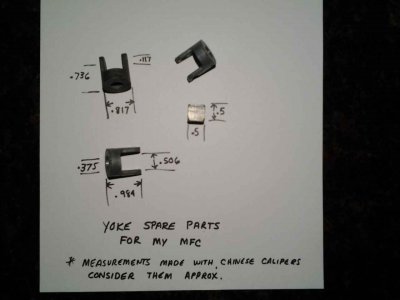

Has anyone made a replacement MF-7 large scope, MF-8 small scope (table feed shaft) and MF-26 yoke?

I recently purchased an Atlas Milling machine with serial number between 005466 and 008123 (identified from manual as the serial number plate is missing). The MF-26 yoke is broken and the shaft (scope) is missing. I've

had no luck trying to find replacements parts, so I considering making them. I'm hoping someone else has done this and perhaps has a drawing/design for the parts in question.

I recently purchased an Atlas Milling machine with serial number between 005466 and 008123 (identified from manual as the serial number plate is missing). The MF-26 yoke is broken and the shaft (scope) is missing. I've

had no luck trying to find replacements parts, so I considering making them. I'm hoping someone else has done this and perhaps has a drawing/design for the parts in question.