- Joined

- Jan 22, 2023

- Messages

- 75

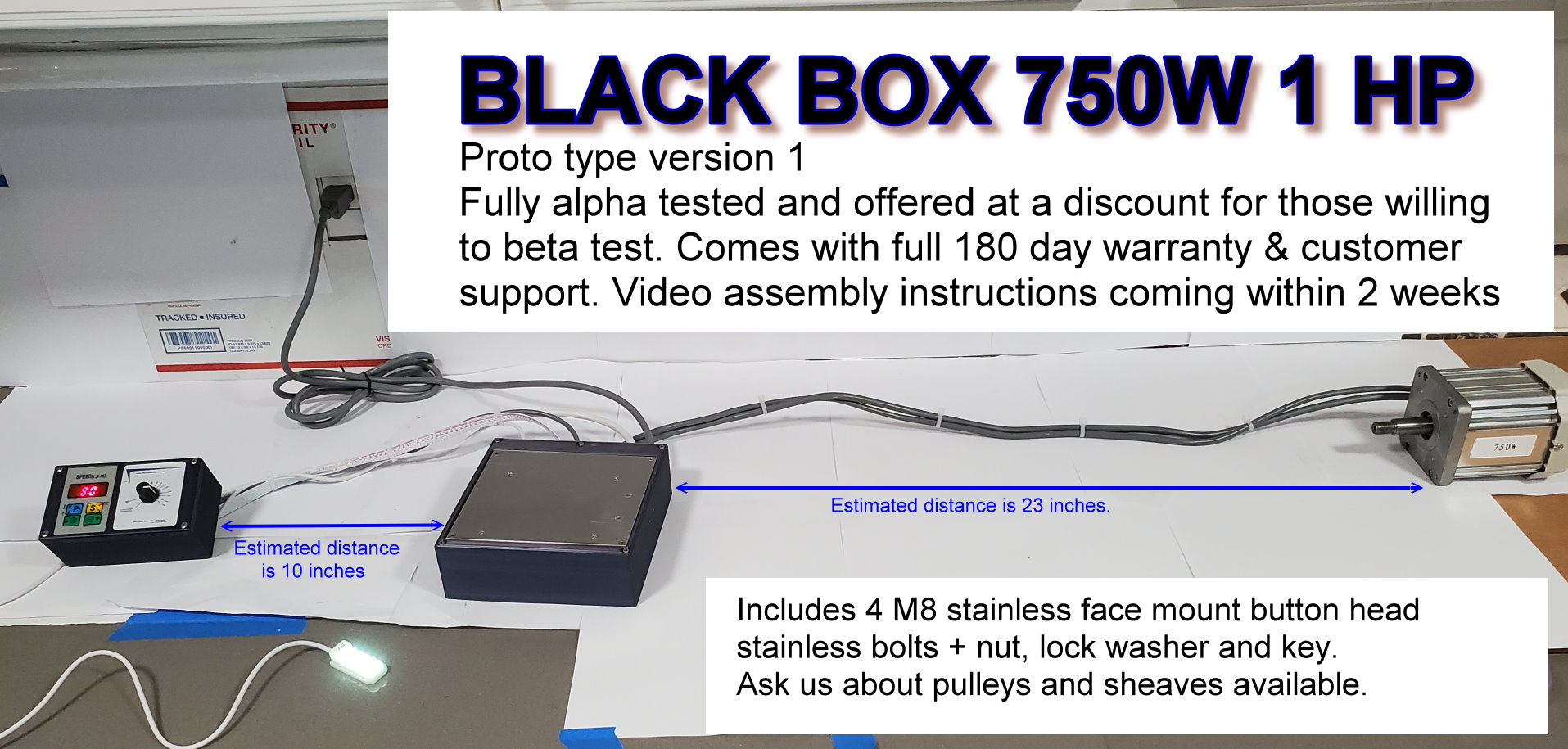

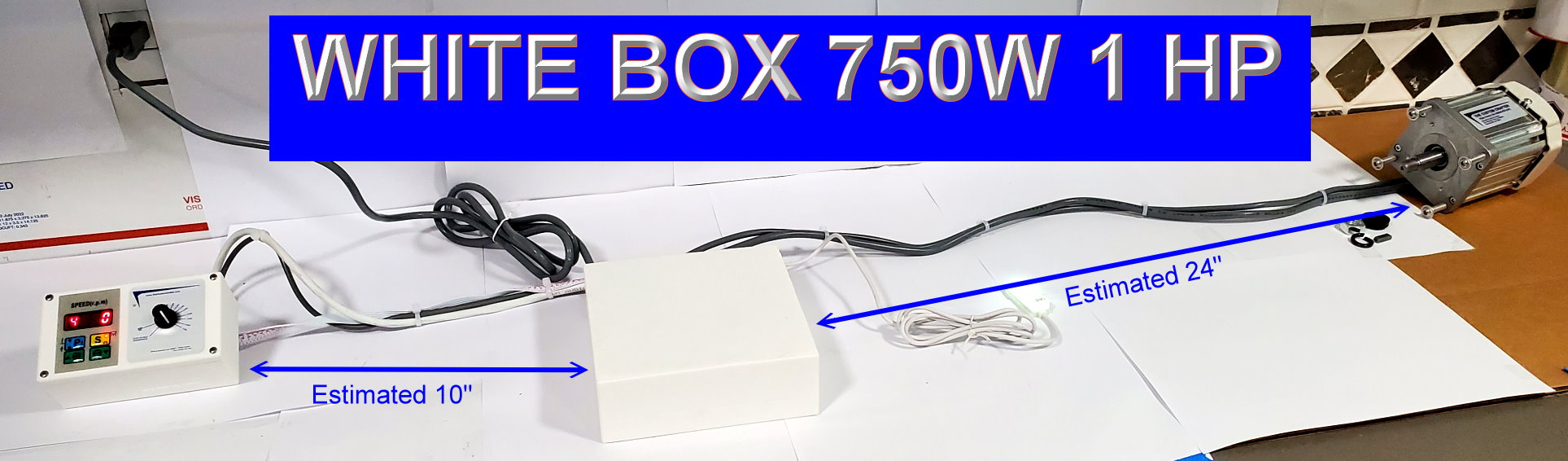

I released 2 of the new Black Box version prototypes for Beta testing today.

1.0 HP 750 Watt Computer Controlled Servo Motor.

Special offer for The Hobby Machinist members:

Mention this forum and I will include the drive pully/sheave of your choice at no extra cost.

These are first version fully Alpha tested prototypes.

They are selling at reduced price because if you buy it, you are Beta testing it.

We will back you with a 180 warranty but expect you to work closely with us

should anything fail.

Find them here:

https://www.servomotorkit.com/produ...or-external-1-0-hp-10-nm-torque-300-4-500-rpm

1.0 HP 750 Watt Computer Controlled Servo Motor.

Special offer for The Hobby Machinist members:

Mention this forum and I will include the drive pully/sheave of your choice at no extra cost.

These are first version fully Alpha tested prototypes.

They are selling at reduced price because if you buy it, you are Beta testing it.

We will back you with a 180 warranty but expect you to work closely with us

should anything fail.

Find them here:

https://www.servomotorkit.com/produ...or-external-1-0-hp-10-nm-torque-300-4-500-rpm