- Joined

- Jul 26, 2011

- Messages

- 4,142

Camera makes the shaft look tapered !

I'm pretty sure that was "auto corrected" from "Dremel"...

Sent from my iPhone using Tapatalk

I hadn't noticed but I guess it does look that way. It is a staight 1/2" diameter shaft.Camera makes the shaft look tapered !

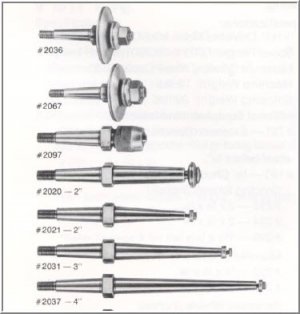

Wow you are doing great work. I'm going to make some variants of these Themac extension spindles. Finding the right size of ID grinding wheels in smallish diameters has been a bit of am ordeal so it might actually be easier to make spindles to match the ones I can get. Anyway, from what I can determine, the spindles are not hardened & re-ground. Personally I'd be a little leary of introducing any run out in them from quenching drill rod, but recognize I'm a newbie at all this.

I'm not sure why but wanted to point out they tend to use large face washers on the larger (~3") diameter wheels.

Also FWIW, the typical 0.250" shanked mounted stones tend to have quite different actual shaft diameters depending on which part of Asia they come from (despite what N-Am tool catalog you buy from). They might even be metric like 6mm or something, so just be aware regarding your collet ID.

That's good to know. I'm familiar with McMaster, unfortunately they don't ship to Canada ...but I have my ways... You are fortunate to have a 1-stop supplier with extensive stock like that.I get good ones from McMaster Carr. .750 diam. .500 or .750 long and will dress to suit me.

I have the same motor, can you post the ebay link to the drive (motor controller)??I picked up a DC drive for 1 1/2 hp motor for $28 on eBay. I got it hooked up today to test run the grinder.

View attachment 131321

It runs good after tweaking the bearing preload. I gotta get the belt guard done . This thing scares the crap outta me at 8000 rpm. Also got to get a small box to mount the drive in. It is getting close to ready to use.