- Joined

- Jan 6, 2017

- Messages

- 1,214

What are you guys using for rendering CAD images?

Most CAD programs have basic rendering, built in, but they don't have many features.

For more advanced stuff, Keyshot and Renderman seem to be pretty popular, though pretty $$$.

Keyshot comes free with Alibre's flagship "Design Expert" CAD software, but I ended up getting "Design Pro", which doesn't come with photorealistic rendering.

I've been playing around with Simlab's free rendering program, "Composer Lite". It seems pretty solid so far.

The 150$ paid version, Composer Pro, can also do motion animation, but I havn't used it.

My practice models from Alibre, a camlock Stud and face mill:

And the image from Simlab Composer Lite:

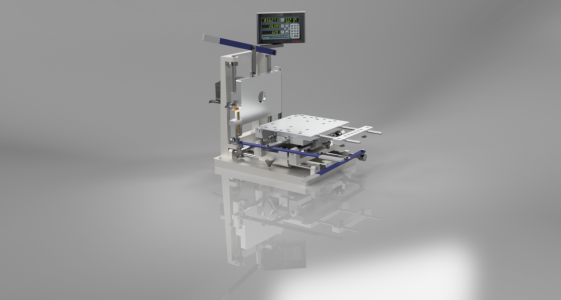

My QC toolpost design, from Alibre CAD:

The Simlab Render:

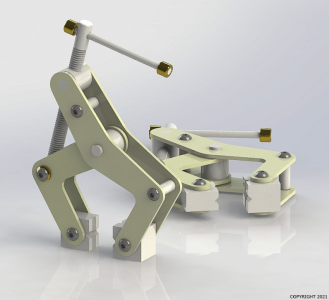

Here's a lathe carriage stop I worked on the past couple days:

And the image rendered in Composer Lite:

I don't think Keyshot has a free version, but I hear that RenderMan from Pixar has a non-commercial free version. Anyone tried it?

Most CAD programs have basic rendering, built in, but they don't have many features.

For more advanced stuff, Keyshot and Renderman seem to be pretty popular, though pretty $$$.

Keyshot comes free with Alibre's flagship "Design Expert" CAD software, but I ended up getting "Design Pro", which doesn't come with photorealistic rendering.

I've been playing around with Simlab's free rendering program, "Composer Lite". It seems pretty solid so far.

The 150$ paid version, Composer Pro, can also do motion animation, but I havn't used it.

My practice models from Alibre, a camlock Stud and face mill:

And the image from Simlab Composer Lite:

My QC toolpost design, from Alibre CAD:

The Simlab Render:

Here's a lathe carriage stop I worked on the past couple days:

And the image rendered in Composer Lite:

I don't think Keyshot has a free version, but I hear that RenderMan from Pixar has a non-commercial free version. Anyone tried it?

Last edited: