- Joined

- Jan 2, 2018

- Messages

- 586

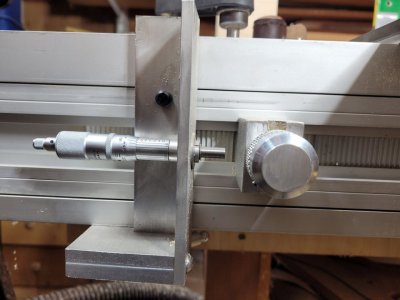

I have a woodrat I modified with DRO on x, and z and a stop with a thousandths micro adjust on the x( mitutoyo mic head) . I also have a multirouter. With a top mounted router it is much easier to pick up lines ( for dovetails , mortises and tenons.) This is for wood work , light brass or aluminum. Definitely is messy.Yea, I had juryrigged a DRO install on the Multirouter 15 years ago and decided to re-design the DRO system to my now higher standards. LOL I decided to reverse engineer the entire machine to test my Fusion 360 skills and help the F360 team make some UI improvements and fix some bugs. Attached are the drawing files that illustrate the encoder/scale mounting and all the custom brackets that I just finished and are now at the anodizing facility.