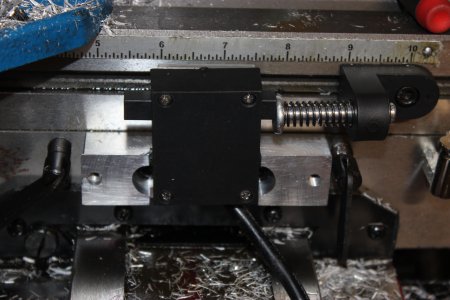

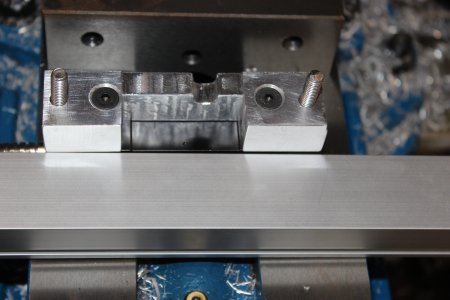

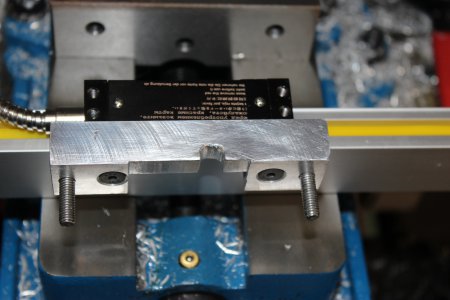

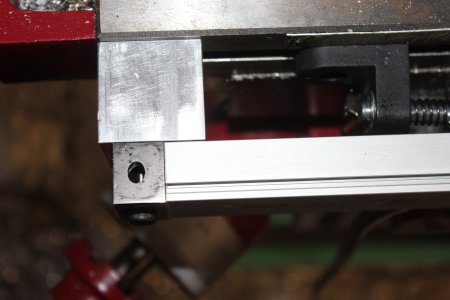

I am pretty pleased with my Central Machinery mill, given its cost. I do wish it had a variable speed motor (future upgrade?), rather than cone pulleys and V-belts, and I do wish it had just a few more inches of vertical travel on the knee. Of course, no mill can really call itself a mill if it doesn't have a DRO (OK, so I am a milling machine snob!), and operations on the X-axis are just absurd without a motor drive. The milling itself is bad enough without an automated X-axis, but moving the bed around between operations is just plain tedious and way, way too slow. Given all that...

Last edited: