The 3d printed gears seems like a good option, and probably fairly cheap. Next thing to do is open the headstock and have a look inside there. I did switch through the gears and turn by hand and it seemed to go through all the gears fine.The ways look better close-up than I expected from your first photo.

A wire brush wheel on a bench grinder might clean up those existing gears quickly.

(face mask and glasses recommended)

Also look into 3D-printed plastic gears, some new lathes come with at least one plastic gear as a "fuse" for crashes.

Brian

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Enterprise 1550 lathe restore

- Thread starter JMan23

- Start date

- Joined

- Apr 30, 2015

- Messages

- 11,307

It comes down to the spindle bearings, if you can get by without replacing those it's worthwhile to fix the rest up- otherwise I would hesitate

to put much money into it

The bedwear doesn't look too terrible. It may have been scrapped for other reasons besides wear

to put much money into it

The bedwear doesn't look too terrible. It may have been scrapped for other reasons besides wear

- Joined

- Nov 22, 2022

- Messages

- 358

Like Mark says,It comes down to the spindle bearings, if you can get by without replacing those it's worthwhile to fix the rest up- otherwise I would hesitate

to put much money into it

The bedwear doesn't look too terrible. It may have been scrapped for other reasons besides wear

I would pull the top cover off of the gearbox, And see if if it's all rusted up inside. There will most likely be pitting/rust above the oil level.

Hey guys, it's been a while, I've been working on my shop and haven't had time for the lathe.

So I got my inverter in for it. Anybody here ever run a 3ph lathe on an inverter? It seems pretty straight forward but wanted to see if anybody has any advice or tips about it.

So I got my inverter in for it. Anybody here ever run a 3ph lathe on an inverter? It seems pretty straight forward but wanted to see if anybody has any advice or tips about it.

- Joined

- Jan 2, 2019

- Messages

- 6,526

Like one of these?

www.northamericaphaseconverters.com

www.northamericaphaseconverters.com

I've used them for a few different machines, the only thing to keep in mind is where the generated leg is hooked up.

JOhn

Static Phase Converters | Electronic Phase Converters for Sale

Get consistent motor power with a static phase phase converter! These American-made static phase converters come with an included lifetime warranty.

I've used them for a few different machines, the only thing to keep in mind is where the generated leg is hooked up.

JOhn

No, like one of these https://m.vevor.com/variable-freque...XHgIH3jq8RBIilUoVTZXE3Rbww61TsnYaAuY6EALw_wcBLike one of these?

Static Phase Converters | Electronic Phase Converters for Sale

Get consistent motor power with a static phase phase converter! These American-made static phase converters come with an included lifetime warranty.www.northamericaphaseconverters.com

I've used them for a few different machines, the only thing to keep in mind is where the generated leg is hooked up.

JOhn

- Joined

- Jan 2, 2019

- Messages

- 6,526

I've put VFD's on two of my lathes and really like having the control they provide. The other type of phase converter is convenient for when you want to keep the controls stock and don't want to get into a big conversion right away.

The main thing to know is VFD's have to be hooked directly to the motor. That means any controls on the machine itself won't work until you integrate them with the VFD. If you like you can controll on/off, fwd/rev, and speed directly from the VFD box but if you want to use the levers and buttons on the machine itself you'll need to read up on control systems and modify what came with your lathe.

If you want to see what's possible you can look for threads here by/with @mksj, lots of us have converted machines but he's the resident expert and always seems willing to help.

But, basically you can disconnect the motor from any existing controls and just wire the three power lines to your VFD to get the machine up and running. Tons of threads on here about conversions both simple and complex but honestly if I was working on that machine I'd go with a static converter first. Reason being is there appears to be lots of controls, and the static converter will be the quickest way to power it up and asses it's condition. Good thing with a static is you can run with it for a while, then change it over to a rotary converter later on with the addition of another 3 phase motor if you choose to go that way.

So, I'd definitely recommend doing some research on the differences between VFD's, static and rotary phase converters. I've done business with North American several times and have been happy with their products and service. It looks like your machine may need some evaluation before you decide what direction to go with it. The static converter is the quickest path to three phase from your household 240v single phase, you can spend your time working on the machine itself rather than trying to figure out control systems, provided you eventually want it working as designed.

If you've already bought the VFD and want to see how the gearbox sounds after you do an oil change and cleanup, all you need to do is disconnect the motor and wire it straight in. But, unless you're ready to dive into some serious electronics before even working with the machine the static would be the way to go IMHO.

John

I wish I knew about the static converters!I've put VFD's on two of my lathes and really like having the control they provide. The other type of phase converter is convenient for when you want to keep the controls stock and don't want to get into a big conversion right away.

The main thing to know is VFD's have to be hooked directly to the motor. That means any controls on the machine itself won't work until you integrate them with the VFD. If you like you can controll on/off, fwd/rev, and speed directly from the VFD box but if you want to use the levers and buttons on the machine itself you'll need to read up on control systems and modify what came with your lathe.

If you want to see what's possible you can look for threads here by/with @mksj, lots of us have converted machines but he's the resident expert and always seems willing to help.

But, basically you can disconnect the motor from any existing controls and just wire the three power lines to your VFD to get the machine up and running. Tons of threads on here about conversions both simple and complex but honestly if I was working on that machine I'd go with a static converter first. Reason being is there appears to be lots of controls, and the static converter will be the quickest way to power it up and asses it's condition. Good thing with a static is you can run with it for a while, then change it over to a rotary converter later on with the addition of another 3 phase motor if you choose to go that way.

So, I'd definitely recommend doing some research on the differences between VFD's, static and rotary phase converters. I've done business with North American several times and have been happy with their products and service. It looks like your machine may need some evaluation before you decide what direction to go with it. The static converter is the quickest path to three phase from your household 240v single phase, you can spend your time working on the machine itself rather than trying to figure out control systems, provided you eventually want it working as designed.

If you've already bought the VFD and want to see how the gearbox sounds after you do an oil change and cleanup, all you need to do is disconnect the motor and wire it straight in. But, unless you're ready to dive into some serious electronics before even working with the machine the static would be the way to go IMHO.

John

I don't know how I never came across those when I was googling 3ph converters. I did already purchase the vfd. I'll just wire it directly to the motor for now, and later I can integrate the various switches into the vfd.

- Joined

- Jan 2, 2019

- Messages

- 6,526

Honestly, if you decided to purchase a static converter it will be a very small addition to the cost of this project. But, it's easy enough to disconnect the motor and that way any issues with the wiring won't keep you from firing it up.I wish I knew about the static converters!

I don't know how I never came across those when I was googling 3ph converters. I did already purchase the vfd. I'll just wire it directly to the motor for now, and later I can integrate the various switches into the vfd.

Post some more pictures if you've made progress....

John

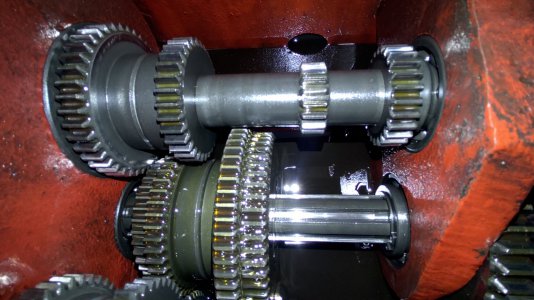

I got the gearbox cover off today and man it looks gorgeous inside. Shiny clean and oiled.

For the speed change lever, should it have a detent to snap into each gear? Right now it just smoothly rotates. Also what does the lever coming straight out of the speed dial? It won't go all the way to the right into the second position?

Also what is the S shaped tube for, the cover has a plastic cap on it to access that.

For the speed change lever, should it have a detent to snap into each gear? Right now it just smoothly rotates. Also what does the lever coming straight out of the speed dial? It won't go all the way to the right into the second position?

Also what is the S shaped tube for, the cover has a plastic cap on it to access that.