- Joined

- Jun 21, 2014

- Messages

- 40

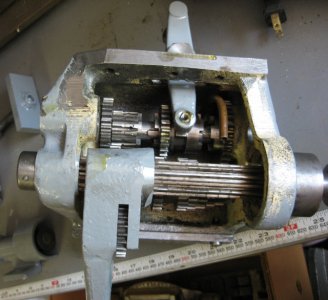

Its been a while but I got quite a bit done on my rebuild. I finished up the headstock and it went pretty smooth. Below are some before and after pictures. By the way I figures out if I deleted some of the pictures in one of my other posts it will now allow me to post pics, ) I will be posting some pictures of the gearbox later.

) I will be posting some pictures of the gearbox later.

Cant wait to get this finished.

Cant wait to get this finished.

it's about an inch long.

it's about an inch long.

I still have to finish leveling it, (it's close) and refinishing all the tags.

I still have to finish leveling it, (it's close) and refinishing all the tags.